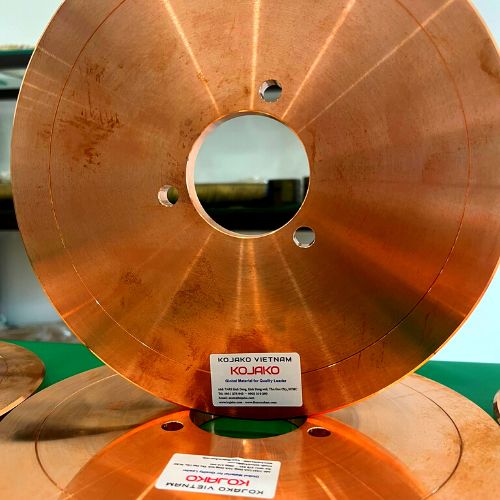

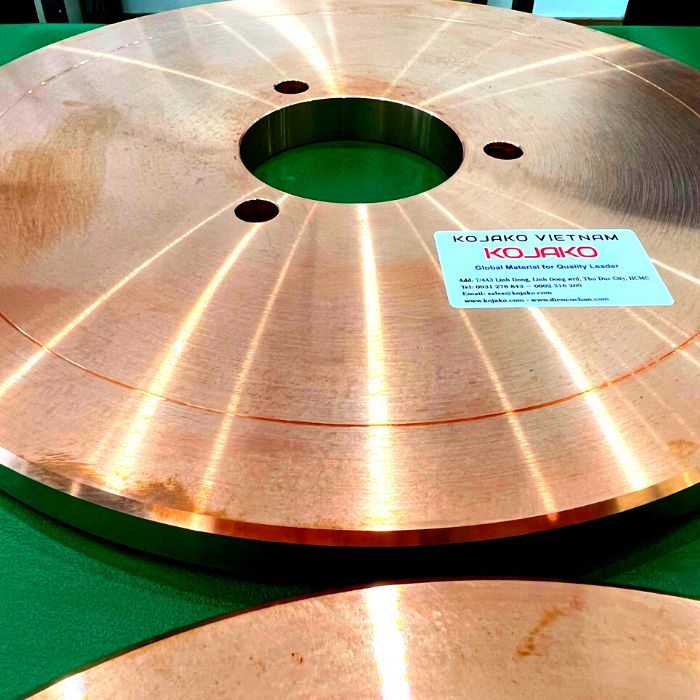

Resistance Seam Welding Wheel C18150

Seam Welding Wheel

Resistance Seam Welding Wheels Copper C18150, also known as resistance seam welding, is identical to the principle of spot welding. A beautiful, flawless and penetrating weld line is created by the current and pressure used to properly weld two similar or different materials together. However, Resistance Seam Welding Wheels Copper C18150 is usually made of C18150 chromium copper alloy. One of these two Seam welding wheels is driven and rolls on two flat surfaces and contacts at the center of the welding point. As the two workpieces pass, welding spots are created by high current and voltage pulses. Above a certain pulse frequency, the welding spots can even overlap and a continuous weld line is created.

Resistance Seam Welding Wheel is perfectly suitable for welding water tanks or steel plates together, creating high quality welds with absolute performance and short welding time. However, to ensure this, the material used to make Resistance Seam Welding Wheels Copper C18150 has suitable properties.

Resistance Seam Welding Disc

Chemical - Mechnical Properties C18150

- Copper (Cu)= 98.0 ~ 99.0%

- Chromium (Cr)= 0.5 ~ 1.5%

- Ziconium (Zr)= 0.05 ~ 0.25%

- Electrical Conductivity (%IACS)= 80.0 ~ 85.0%

- Tensile strength= 50 ~ 70 KSI

- Density= 8.89

- Hardness= 72 ~ 85 HRB

Đĩa Hàn Lăn Crom

- Material: Chromium Copper Alloy (CuCr1Zr)

- Size: Width 120 ~ 500mm and thickness 10 ~ 30mm.

- Origin: Genuine imported goods from Korea - Europe - Japan

- Material composition and hardness are clearly stated above.

- Application: Welding of water tanks, oil tanks, dishwashing lavabors...

- All C18150 Alloy Copper Welding Roller products have a certificate of origin and material inspection issued by the manufacturing country.

Đĩa Hàn Crom

Please contact us for advice and wholesale pricing for customers if the quantity is over 10 soldering roller discs/order. KojakoVietnam is committed to quality and 100% free returns within 24 working hours.