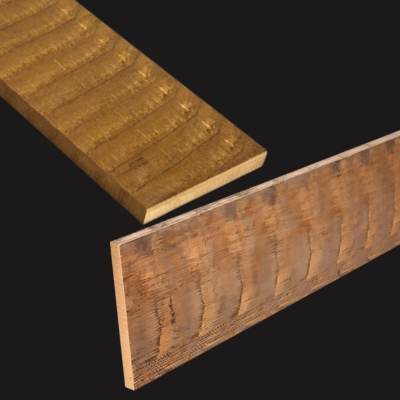

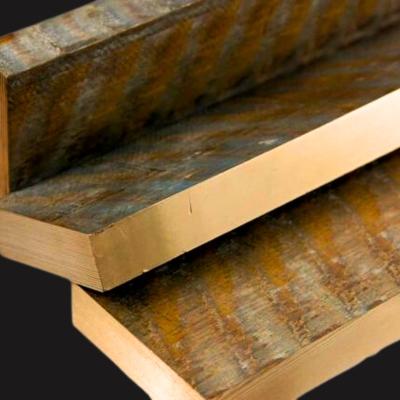

Gunmetal Bronze SAE 660 C93200 Leaded Bronze is a general purpose leaded tin bronze bearing and bushing material. It has excellent machining properties, good hardness, strength and wear resistance with excellent anti-frictional qualities.

Gunmetal Bronze SAE 660 C93200 Leaded Bronze is a general purpose leaded tin bronze bearing and bushing material. It has excellent machining properties, good hardness, strength and wear resistance with excellent anti-frictional qualities. The alloy is not subject to dezincification and has reasonable corrosion resistance to sea water and brine making it suitable for pump and valve components. Gunmetal Bronze C93200 SAE660 is suitable for bearings having medium loads and speeds with adequate lubrications. SAE 660 has very similar components to LG2 bronze albeit with slightly different proportions. This means that both metals can be used interchangeably in most cases.

The composition of C93200 SAE660 is strictly controlled as are the casting conditions. All Kormax bronze is manufactured using finely controlled continuous or centrifugal casting techniques to ensure that hardness and strength is superior to sand-casting methods. This also means that the material has a fine grain structure and is free from porosity.

Gun Metal Bronze SAE660 is a type of bronze alloy that contains high levels of tin and zinc, making it an ideal material for use in applications where strength, durability, and resistance to wear are important. This alloy is commonly used in the manufacturing of bearings, bushings, and other components that require high levels of performance.

In addition to its mechanical properties, Gun Metal Bronze SAE660 also has excellent corrosion resistance, making it suitable for use in marine environments or other harsh conditions. Its attractive bronze color also makes it a popular choice for decorative applications. Overall, Gun Metal Bronze SAE660 is a versatile and reliable material that can be used in a wide range of applications. Its unique combination of strength, durability, and corrosion resistance make it an ideal choice for many industries.

Bronze Bars C93200 SAE 660 are high quality smooth machine finish stock for general utility bearings and bushings and which are highly resistant to impact, wear and corrosion. It is a general purpose bearing alloy possessing good anti-friction properties, ample strength and hardness, adequate ductility and excellent machinability. It is used as bearings, bushings, light duty gears and sprockets, impellers, wear strips, plates, automotive fittings and washers. It is used extensively in pumps, cylinders, machine tools, earth moving machinery and a myriad of general purpose applications.

Application

For Fasteners Washers Industrial Bearings for Cranes, Trunion Bearings, Roll Neck Bearings, Rolling Mill Bearings, Linkage Bushings for Presses, Fuel Pump Bushings, Water Pump Bushings, Diesel Engine Wrist Pin Bushings, Forging Press Toggle Lever Bearings, Hydraulic Press Stuffing Box, Hydraulic Press Main Lining, Insert Bearings, Bearings, Thrust Washers, Pumps, Bushings, Machine Parts, Pump Impellers, General Purpose Bushings, Fittings, Pump Fixtures, Main Spindle Bearings, Machine Tool Bearings...

Chemical Composition

(%max, unless shown as range or min)

|

|

Cu

|

Al

|

Sb

|

Fe

|

Ne+

|

P

|

Si

|

S

|

Sn

|

S

|

Zn

|

|

Min/Max

|

81.0-85.0

|

0.005

|

0.35

|

0.2

|

6.0-8.0

|

1.0

|

1.5

|

0.005

|

6.3-7.5

|

0.1

|

2.0-4.0

|

* Ni value includes Co.

Note: Cu + Sum of Named Elements, 99.0% min.

Applicable Specifications

* ASTM B505

* SAE J461, SAE J462, SAE 660

Fabrication Processes

* Continuous Casting

Fabrication Properties

Mechanical Properties (ASTM B505)

|

Tensile Strength, minA

|

Yield Strength, at 0.5% Extension Under Load, minA

|

Elongation in 2 in.

or 50 mm, min, %

|

|

ksi

|

MPa

|

ksi

|

MPa

|

|

35

|

241

|

20

|

138

|

10

|

* Minimum tensile strength and yield strength shall be reduced 10% for cast bars having a cross section, thickness, diameter, or wall of 4 in. (102 mm) or more. The cross sections are the diameter of a round solid, the distance across the flats of a solid hexagon, the thickness of a rectangle, and the wall thickness of a tube.

Physical Properties

|

|

US Customary

|

Metric

|

|

Melting Point – Liquidus

|

1790 F

|

977 C

|

|

Melting Point – Solidus

|

1570 F

|

854 C

|

|

Density

|

0.322 lb/in3 at 68 F

|

8.91 gm/cm3 at 20 C

|

|

Specific Gravity

|

8.91

|

8.91

|

|

Electrical Resistivity

|

85.9 ohms-cmil/ft at 68 F

|

14.29 microhm-cm at 20 C

|

|

Electrical Conductivity

|

12 %IACS at 68 F

|

0.07 MegaSiemens/cm at 20 C

|

|

Thermal Conductivity

|

33.6 Btu · ft/(hr · ft2·°F) at 68 F

|

58.2 W/m ·°K at 20 C

|

|

Coefficient of Thermal Expansion

|

10.0·10-6 per °F (68-212 F)

|

18.0·10-6 per °C (20-100 C)

|

|

Specific Heat Capacity

|

0.09 Btu/lb/°F at 68 F

|

377.1 J/kg · °K at 20 C

|

|

Modulus of Elasticity in Tension

|

14500 ksi

|

100000 MPa

|

Application Standard

-

AS1565 C93200

-

ASTM B505

-

B271 – C93200

-

SAE 660