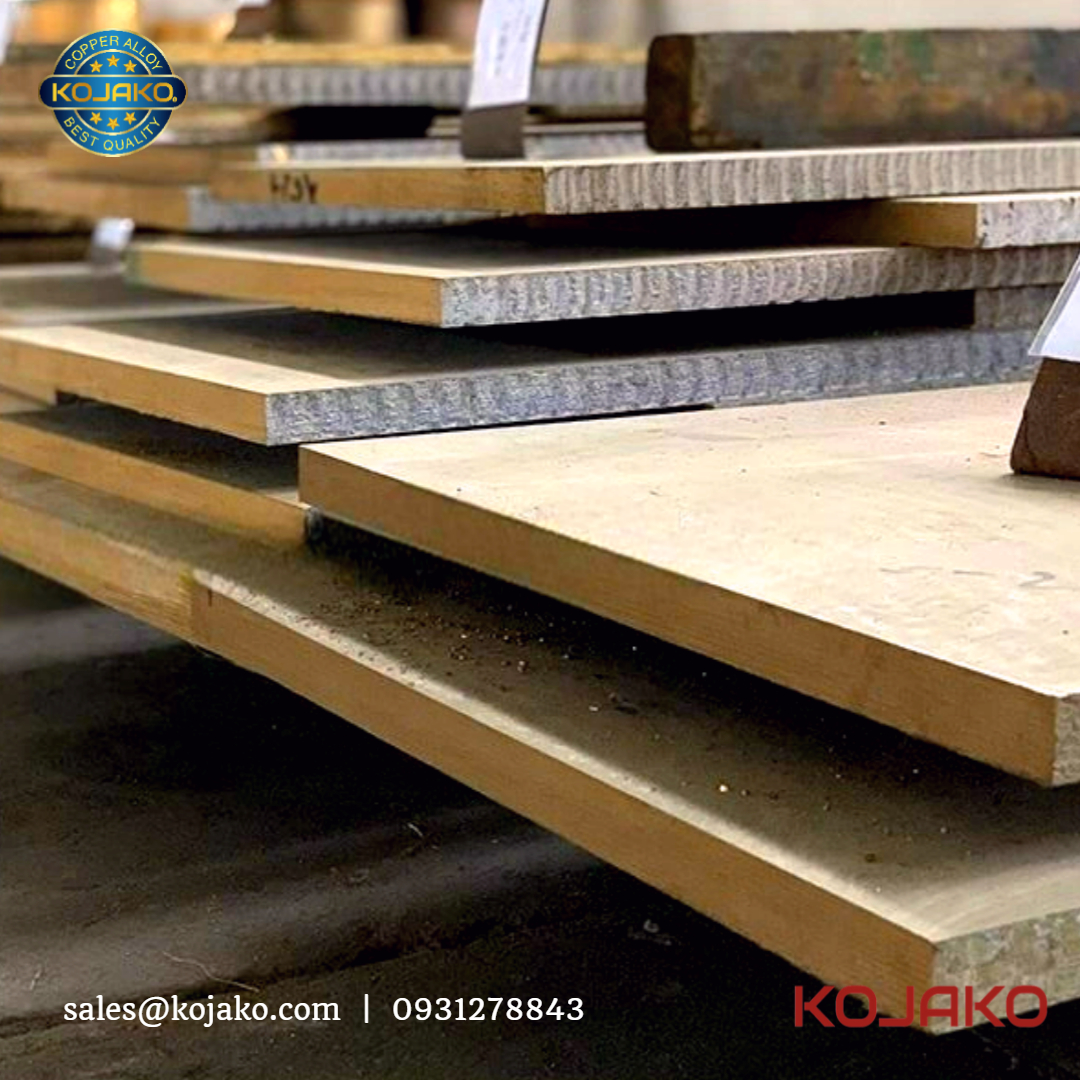

BC3 Tin Bronze

BC3 CAC403 Tin Bronze With High Strength - Excellent Resistance to Friction & Abrasion - Chemical & Sea Water Corrosion. High Antioxidation & Electrical Conductivity.

BC3 Tin Bronze is a special material in the engineering industry. It is produced by smelting copper metal with several other alloys such as tin, lead, aluminum, zinc and lead to create an alloy with optimal properties and properties. Furthermore, BC3 JIS Copper Alloy material is manufactured based on JIS (Japanese Industrial Standards), ensuring high quality and reliability. Thanks to its high versatility, BC3 JIS Copper Alloy can be applied in many different technologies, from machinery manufacturing to electronics and automobile manufacturing.

One of the key features of BC3 Tin Bronze is its resistance to corrosion. With a high percentage of lead, it has very good corrosion resistance, especially when exposed to highly corrosive environments such as seawater and chemical environments.

|

BC3 JIS | CAC403 JIS | C90500 ASTM - Mechanical Properties |

Standard | ||||

| %Cu | 86.5~89.5 | %Pb | max 1.0 | JIS | ASTM |

| %Sn | 9.0 ~ 11.0 | %Ni | max 1.0 | BC3 | C90500 |

| %Zn | 1.0 ~ 3.0 | %Fe | max 0.2 | CAC403 | |

| Tensile strength (N/mm²) | min.250 | ||||

| 0.5% Yeild strength (N/mm²) | - | ||||

| Elogation (%) | min.15 | ||||

| Hardness Brinell | min. 73 | ||||

Although BC3 JIS Copper Alloy has average hardness, on the contrary, it has very good durability. It can withstand great pressure and friction without deformation or damage. This makes it an ideal choice for part machining applications that require high durability, such as in the production of light and heavy industrial machinery and equipment parts.

BC3 Tin Bronze JIS material also has good thermal and electrical conductivity. This makes it very suitable in applications that require the transfer of heat or current, such as in the production of electrical and electronic components.

The applications of BC3 Copper Alloy are very diverse. It is widely used in the engineering industry, including machinery manufacturing, industrial equipment, electronic parts, water pipes and fuel systems. In particular, in applications requiring high corrosion resistance, hardness and durability, BC3 JIS Copper Alloy is a popular choice.

BC3 JIS Copper Alloy can also be machined to create products with diverse sizes and shapes, such as tubes, bars, plates, and complex components. This facilitates the application of this material in diverse and demanding manufacturing projects that require high precision.

Based on its excellent applications and features, BC3 JIS Copper Alloy has become a top choice for manufacturers and engineers worldwide. With guaranteed quality and application flexibility, it will continue to grow and contribute to the success of industrial projects. Specifically, they are processed into main details such as high load bearings & bushings, straight gears & inclined teeth, valve body & valve details such as valve stem, valve seat, pump details...

Features of BC3 Copper Alloy include:

1. High hardness and durability: BC3 copper alloy has good hardness and durability. With the right alloy structure, it is capable of withstanding pressure and friction without deformation or damage. This makes it an ideal material for applications that require high resistance such as in the manufacture of industrial machinery and equipment.

2. Corrosion resistance: BC3 copper alloy has good corrosion resistance. With a high percentage of lead, it has good corrosion resistance, especially when exposed to highly corrosive environments such as seawater and chemical environments.

3. Thermal and electrical conductivity: BC3 copper alloy has good thermal and electrical conductivity. This makes it suitable in applications that require the transfer of heat or electrical current, such as in the manufacture of electronic parts.

4. Anti-oxidation properties: BC3 copper alloy has good anti-oxidation properties. Its special alloy composition helps protect the surface from corrosion and forms an anti-oxidation layer, which prolongs the life and durability of the material.

5. Machining features: BC3 copper alloy has good machinability. With its pure structure and good processability, it is easily machined into various shapes and sizes to suit the specific requirements of engineering applications.

In summary, BC3 JIS Copper Alloy is a special material in the engineering industry, with good corrosion resistance, hardness and durability. With the ability to conduct heat and electricity. If you are looking for a reliable and versatile material, BC3 Tin Bronze JIS is a great choice. Contact us today for more information about the product and to provide JIS Quality Certificate."