BC6 Copper Alloy: Applications and Benefits in Industry

Copper alloy BC6 is one of the special alloys, widely used in modern industry. With its outstanding properties and corrosion resistance, BC6 Copper Alloy has become an indispensable material in many important applications. This article will help you better understand copper alloy BC6 Copper Alloy and how it plays an important role in the industry.

1. Copper alloy What is BC6 copper alloy?

BC6 copper alloy is a special type of Tin alloy copper, usually containing main components such as Zinc (Zn), copper (Cu), Tin (Sn), Lead (Pb) and a small amount of other additional metals. Added to the BC6 alloy Copper component has higher mechanical properties. The combination of these components creates an alloy with many superior properties, including mechanical strength and corrosion resistance.

2. Material composition BC6 copper alloy

|

CHEMICAL COMPOSITION

|

MECHANICALPROPERTIES

|

|

Sn

|

4.0 - 6.0%

|

Al

|

0 - 0.005%

|

* Tensile Strength

|

min. MPa 200 – 270

|

|

Zn

|

4.0 - 6.0%

|

P

|

0 - 0.05%

|

* 0.2% Proof Stress

|

min. MPa 100 – 110

|

|

Pb

|

4.0 - 6.0%

|

Cu

|

Balance

|

* Elongation

|

min. 6 - 13%

|

3. Application of BC6 copper alloy in industry

Copper alloy BC6 is widely used in various industries due to its versatility and special properties, specifically:

- Aviation and aerospace industry: BC6 copper alloy is often used in the production of aircraft and spacecraft parts. Its corrosion-resistant properties make it the ideal choice for enduring the harsh environments of space.

- Automotive industry: BC6 copper alloy is also used in automobile manufacturing to create highly load-bearing and wear-resistant parts such as bushings, gears, etc.

- Food industry: Due to its optimal stainless and anti-corrosion properties, BC6 Copper Alloy is often used to make parts in food production and packaging machines. Specifically, bushings, sliding bearings, sliding plates, gears, nuts, pump and valve parts... especially for processing replacement parts for hydraulic systems and very effective lifting.

- Metallurgical industry: BC6 copper alloy is able to withstand high temperatures and maintain stable mechanical properties, so it is often used in the field of metallurgical industry and machine manufacturing very effectively.

4. Benefits of using BC6 Copper Alloy

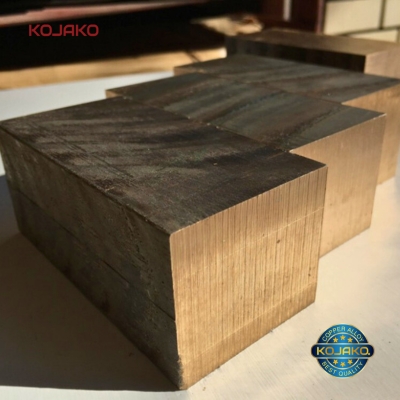

- Mechanical strength: BC6 alloy copper has high mechanical strength, which makes it suitable for the production of high-speed and load-bearing parts. This is determined by the composition of Tin (Sn), Zinc (Zn), Lead (Pb).

- Corrosion resistance: The corrosion resistance of Copper Alloy BC6 is one of its important characteristics. This makes it suitable for applications in wet environments or in contact with corrosive substances, seawater, chemicals, etc.

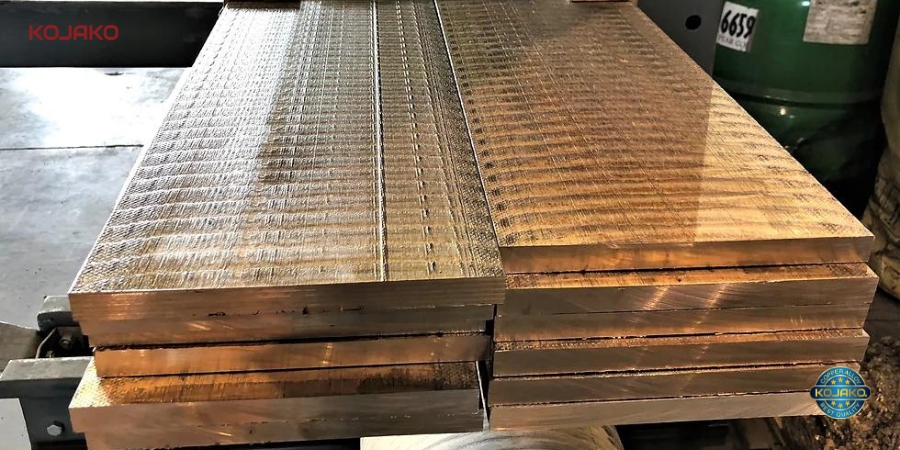

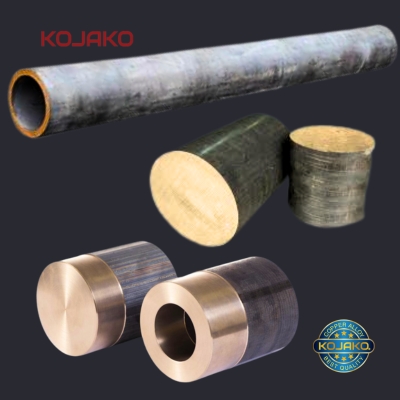

- Versatility: Copper alloy BC6 can be continuous casting, forging, centrifugal casting or machined into different complex shapes, helping to create products. Diverse products for many different applications.

High Temperature Resistance: BC6 copper alloy is resistant to high temperatures and maintains hardness at high temperatures, making it suitable for applications requiring heat resistance.

In summary, Copper Alloy BC6 is an important material in modern industry with many outstanding properties, from corrosion resistance to flexibility and mechanical strength. The wide application in various fields proves the indispensable value of this alloy in today's industrial world.

5. Application Standard

Standards apply Bronze Alloy BC6 (English: Leaded Gunmetal Bronze or Gunmetal Bronze), including: