CAC406 Phosphor Bronze

CAC406 Phosphor Bronze is used in machining mechanical parts that require high durability, as well as good corrosion and abrasion resistance. CAC406 Phosphor Bronze is very suitable for use in the production of machine components, fixtures, valves, air compressor parts, mechanical tools and molds, bearings, or mechanical gears...in industry. In this article, we will learn about the properties, applications and benefits of CAC406 Phosphor Bronze.

Characteristics of CAC406 Phosphor Bronze

- High hardness: CAC406 Phosphor Bronze has higher hardness and durability than regular bronze. This makes it an ideal material for applications requiring high stiffness and strength. Additionally, CAC406 Phosphor Bronze has excellent wear and impact resistance.

- Wear resistance: CAC406 Phosphor Bronze has good wear resistance, helping to increase the life and performance of parts used in corrosive or highly abrasive environments.

- Heat resistance: CAC406 Phosphor Bronze has good heat resistance, can work in high temperature conditions without losing mechanical properties and stability during use.

- Corrosion resistance: With the participation of Tin - Lead - Zinc alloy, CAC406 Phosphor Bronze has good corrosion resistance, especially in acidic environments. This makes it suitable for applications in chemical industries and highly corrosive environments or for lifting equipment. With so many advantages, this CAC406 Copper Alloy helps it withstand high pressure and load suitable for today's heavy industry.

- Machining: CAC406 Phosphor Bronze is easily machined, allowing for precise shaping and machining of intricate parts. This helps save time and costs during the production process.

Conclusion: CAC406 Phosphor Bronze is often used to process mechanical parts that require hardness, durability and corrosion resistance. The use of CAC406 Phosphor Bronze in machining mechanical parts also depends on the specific requirements of each application - machinery system. To ensure correct CAC406 requirements and specifications, specific technical documentation should be consulted or consultation with the manufacturer or specialist mechanical experts.

Main application - CAC406 Phosphor Bronze

- Aviation and space industry: CAC406 Phosphor Bronze is used in manufacturing aircraft parts, such as gears, shafts, and load-bearing parts that require high temperature resistance and good wear resistance. Because CAC406 has superior mechanical properties and wear resistance, it helps improve the durability and longevity of aircraft parts under harsh conditions. Furthermore, CAC406 is also applied to components in the suspension system and control system of aircraft. This ensures the safety and durability of the aircraft during operation.

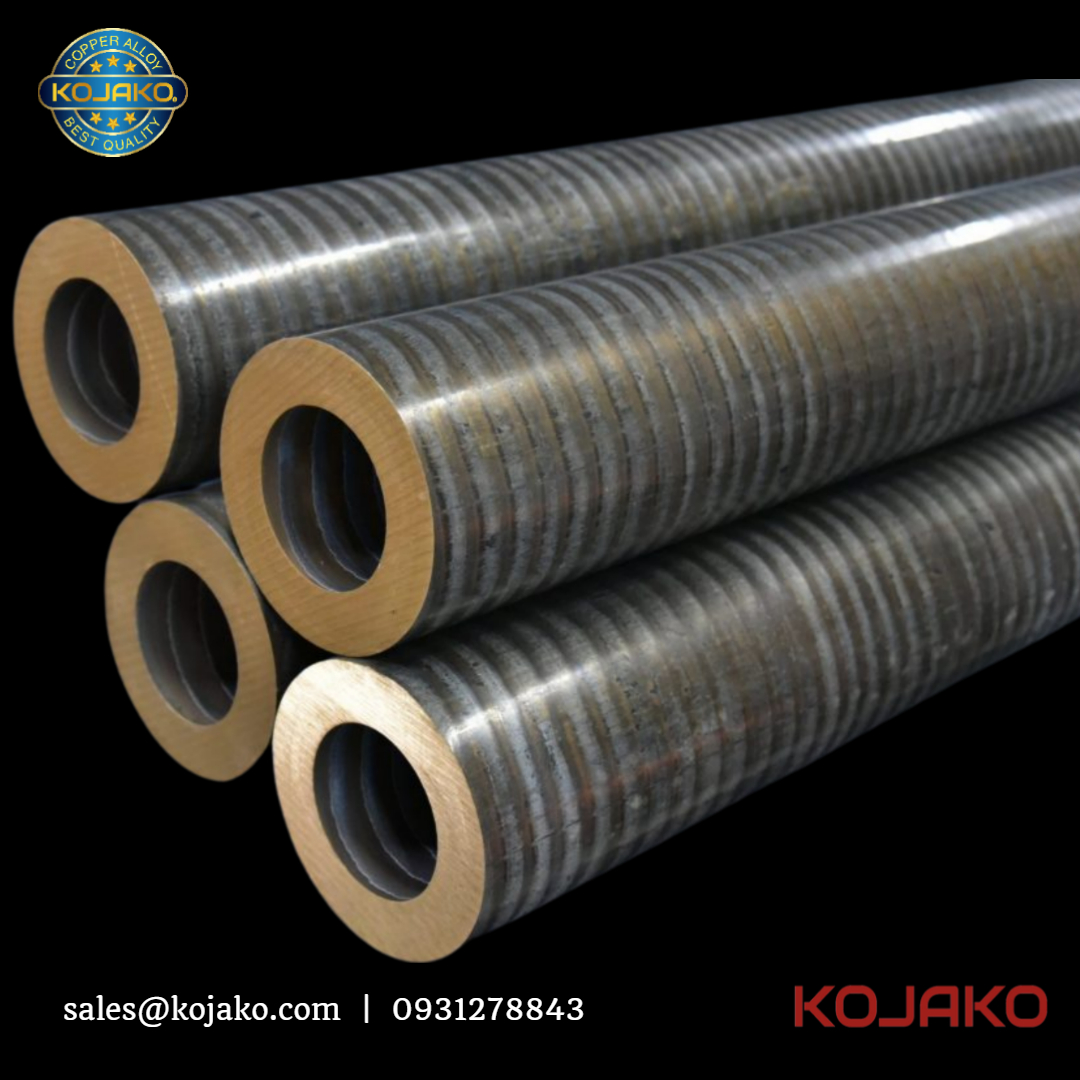

- Energy industry: With its corrosion resistance and good thermal conductivity, CAC406 Phosphor Bronze is also used in making parts in the energy industry, such as oil pipes or flow lines. It helps increase the performance and durability of these systems.

- Electronics industry: CAC406 Phosphor Bronze is used in the fabrication of electronic components that require mechanical strength and stability, such as power tubes and ballasts. Its anti-corrosion and heat-resistant properties make it an ideal material for electronic applications. With good electrical conductivity and corrosion resistance, CAC406 Phosphor Bronze is used in making electronic parts, such as pins and connections of microcircuits and electronic components. It helps ensure the stability and reliability of electronic devices.

- Chemical industry: Due to its good corrosion resistance, CAC406 Phosphor Bronze is used in the production and fabrication of tanks, pipes and machinery parts in the chemical industry.

- Automotive Industry: In the automotive industry, CAC406 Phosphor Bronze is used to produce load-bearing parts, such as shafts or rotors. Thanks to its mechanical properties and corrosion resistance, it helps improve the durability and hardness of components in the automotive transmission system.

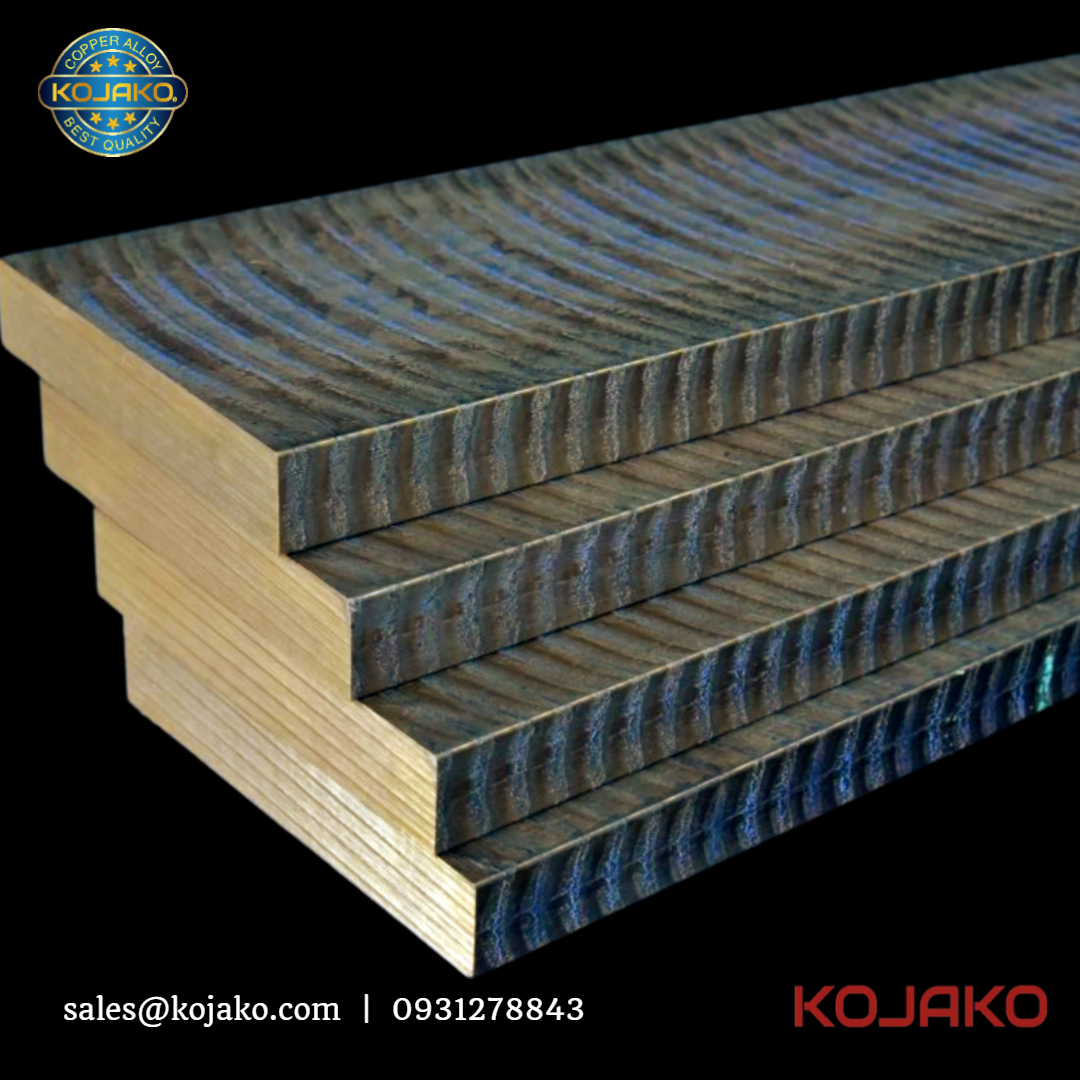

- Precision machine manufacturing industry: CAC406 Phosphor Bronze is used in manufacturing parts such as bearings and cylinders, racks - gears, bushings - sliding bearings - sliders... This helps create the Smooth and completely precise moving parts with high durability and wear resistance, increasing machine performance and longevity.

CAC406 | BC6 JIS | C83600 Mechincal Properties

|

CAC406 | BC6 JIS | C83600 |

Standard | ||||

| %Cu | 83 ~ 87 | %Fe | 4 ~ 6 | JIS | ASTM |

| %Pb | 4 ~ 6 | %Mn | 0 | BC6 | C83600 |

| %Zn | 4 ~ 6 | Balance | 2 | CAC406 | |

| Tensile strength (N/mm²) | min.195 | ||||

| 0.5% Yeild strength (N/mm²) | min. 140 | ||||

| Elogation (%) | min.10 | ||||

| Hardness Brinell | min. 65 | ||||