CAC604 Leaded Tin Bronze

CAC604 Leaded Tin Bronze has many benefits for industrial applications. With its anti-corrosion and high durability properties, the copper alloy CAC604 helps reduce maintenance repair costs - replacing equipment parts or parts. The high thermal and electrical conductivity of CAC604 Leaded Tin Bronze also helps increase the performance of electronic devices and machinery, while improving the performance of equipment systems.

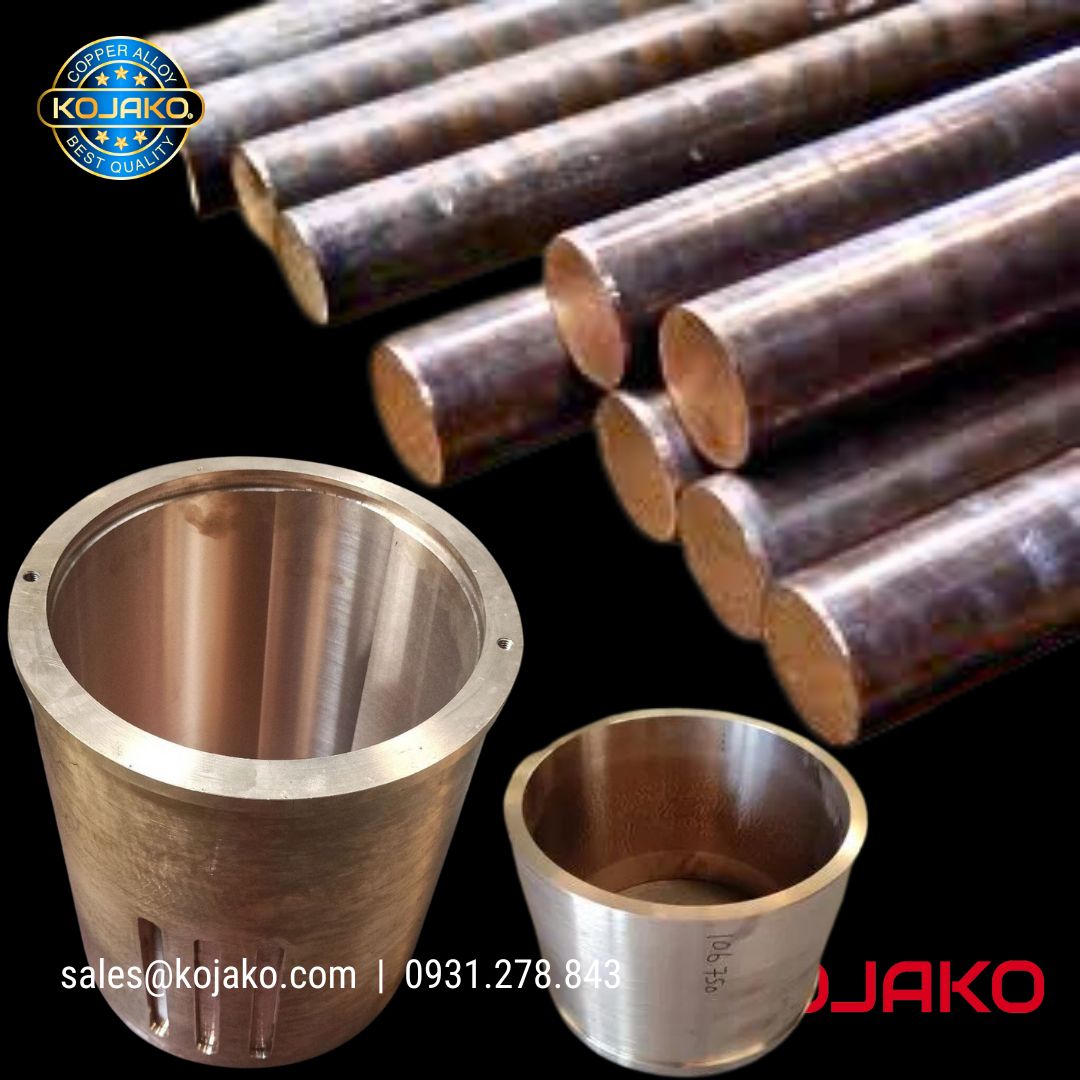

In particular, the outstanding hardness of CAC604 Leaded Tin Bronze helps increase load bearing and reduce elasticity, bringing high efficiency in the production of industrial machinery and equipment parts. With these benefits, CAC604 Leaded Tin Bronze is a perfect choice for industrial applications with high requirements for durability and load resistance. Flexibility in manufacturing and processing is also an undeniable advantage of CAC604 tin-lead alloy. They can be formed into any shape, from thin coils, rods, tubes to complex structures, to suit the specific requirements of different products.

CAC604 Leaded Tin Bronze also features high durability, making it an ideal material for the production of industrial machinery and equipment parts. At the same time, high durability also helps products using CAC604 Leaded Tin Bronze operate well for a long time without causing problems or damage.

Good electrical conductivity: With good electrical conductivity, CAC604 Leaded Tin Bronze is widely used in electronics manufacturing industries. Electronic components manufactured from CAC604 Leaded Tin Bronze are able to withstand large currents and are less susceptible to interference from external factors.

Good machinability: CAC604 Leaded Tin Bronze is considered one of the easiest and most versatile materials to work with. With good machinability, CAC604 Leaded Tin Bronze can be manufactured into products of varying sizes, shapes and thicknesses to suit the needs of different industrial applications.

Overall, CAC604 Leaded Tin Bronze is a very important and highly applicable material in various industries. Thanks to its high durability, corrosion resistance, good electrical conductivity and flexible machining capabilities, CAC604 Leaded Tin Bronze has been widely used to produce products such as machinery parts and electronic equipment. , marine spare parts and many other industrial products.

CAC604 Leaded Tin Bronze is a very strong, durable and consistently hard material used in a variety of industrial applications. With main components of copper, lead and tin, CAC604 Leaded Tin Bronze has good corrosion resistance, helping to increase the lifespan of industrial products. In particular, CAC604 Leaded Tin Bronze also has the ability to increase load bearing and reduce elasticity, helping to increase the stability and reliability of industrial applications.

Because of this special feature, CAC604 Leaded Tin Bronze is widely used in the manufacture of automobiles, machinery, electronic equipment, as well as in the shipbuilding and marine industries. Besides, CAC604 Leaded Tin Bronze is also used in many other applications, from medical devices to household products such as cutlery, pressure cookers, refrigerators, etc.

In the FAQs about CAC604 Leaded Tin Bronze, we can better understand the composition and features of this material. CAC604 Leaded Tin Bronze is made from copper, nickel and aluminum, and is used in industrial applications due to the material's corrosion resistance, high strength and exceptional hardness. Therefore, CAC604 Leaded Tin Bronze is the top choice of many manufacturers in various industries.

CAC604 Leaded Tin Bronze is a very popular material in industrial applications today, especially in environments with high requirements for strength and load-bearing capacity. Manufactured from a mixture of copper, lead and tin, CAC604 Leaded Tin Bronze has many excellent features, including corrosion resistance, durability and a hardness that ensures stability. So CAC604 Leaded Tin Bronze is widely used in various industries such as automotive, aviation and shipbuilding because its features allow use in environments with high humidity and water, chemical, water ingress sea salt. In addition, CAC604 Leaded Tin Bronze is also used in electronics and medical machinery, where strength and hardness are required to ensure device precision and safety.

|

Mechanical Properties |

Physical Properties | Standard Equivalent | |||||

| %Cu | 74.0-78.0 | %Fe | 0.2 | Tensile strength (N/mm²) | min.220 | JIS | ASTM |

| %Sn | 7.0-9.0 | %Ni | 1.0 | Yield strength (N/mm²) | min. 100 | CAC604 | B505 C93800 |

| %Pb | 14.0-16.0 | %Al | 0.005 | Elogation (%) | min.8 | H5115 LBC4 | |

| %Zn | 1.0 | %Si | 0.005 | Hardness (HBW) | min.60 | ||

| %P | 0.005 | %Mn | ~ | ||||

If you are looking for an ideal material for your industrial application, CAC604 Leaded Tin Bronze is the perfect choice for you. With its outstanding advantages, CAC604 Leaded Tin Bronze will bring many benefits to your products, from corrosion resistance to high load-bearing capacity and long-term durability.

Consider CAC604 Leaded Tin Bronze when designing your products to ensure the safety and reliability of your products. Please immediately contact our team of experts specializing in copper alloys - Kojako Vietnam Co., Ltd.