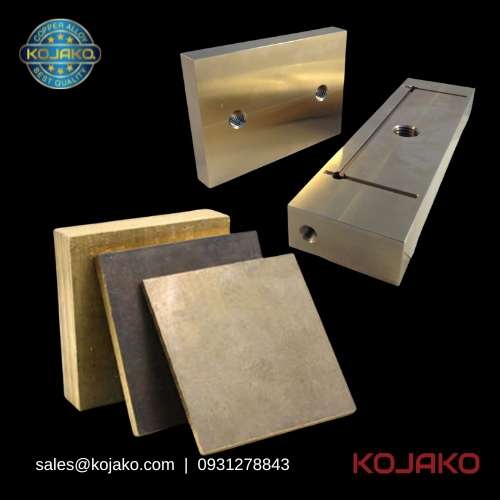

ALBC2 Aluminum Bronze

ALBC2 Aluminum Bronze is a type of brass alloy created by mixing two main metal components: copper (80~88%) and aluminum (8~10.5%), along with small amounts of iron (2.5~5%), nickel (1~3%), and manganese (0.1~1.5%). This alloy possesses high strength, heat resistance, resistance to seawater corrosion, and good wear resistance. It also has optimized mechanical properties, is resistant to corrosion, and has excellent heat treatment capabilities during the annealing and rolling processes, making it suitable for use as a material in various heavy-industry machinery and tools.

Due to its higher hardness compared to mild steel, ALBC2 Aluminum Bronze is used in various types of machinery such as paper manufacturing machines, electrode holders, and clamps used in resistance spot welding. It is also used in the electrical industry, helical and spur gears, worm gears, castings, machine guide equipment, sparkless hand tools, non-magnetic chains and anchors, as well as fan blades, high and low-pressure steam valves.

ALBC2 Aluminum Bronze can be welded using metal inert gas welding and brazing with a specific flux. Its versatility and beneficial properties make it a widely used material in the industrial sector. Its resistance to corrosion, hardness, and good thermal conductivity allow for various applications, such as:

1. Electrical Industry: This material is used in the production of electrical components such as motors, generators, transformers, and other electrical equipment. ALBC2 Aluminum Bronze, with its ability to withstand heavy loads and efficient heat dissipation, is an ideal choice for electrical applications.

2. Automotive Industry: This alloy is used in the manufacturing of automotive parts such as brake discs, suspension components, cylinder blocks, and other parts. ALBC2 Aluminum Bronze's high hardness, corrosion resistance, and good thermal conductivity enhance the performance and durability of automotive components.

3. Aerospace Industry: With its high load-bearing capacity and relative hardness, ALBC2 Aluminum Bronze is used in the production of aircraft and spacecraft parts. This ensures that the parts can withstand harsh environmental conditions and high pressure.

4. Chemical Processing Industry: With its high corrosion resistance, this material is suitable for the production of chemical tanks, containers, piping, and other components used in liquid and chemical processing.

5. Energy Industry: ALBC2 Aluminum Bronze is used in the production of power generators, thermal power plants, and solar energy devices. Its good thermal conductivity is a significant advantage in the energy industry.

6. Maritime Industry: Due to its excellent heat resistance, corrosion resistance, optimized wear resistance, and high hardness, ALBC2 Aluminum Bronze is used to manufacture ship propellers, bearings, gears, pipe linings, valve seats, fan blades, bolts, nuts, safety tools, and more.

These are just a few examples of the wide range of applications for ALBC2 Aluminum Bronze in different industries. Its corrosion resistance, hardness, and thermal conductivity make it a versatile material that provides high performance in various industrial applications.

|

Aluminum Bronze ALBC2 | CAC702 | C95400 |

Standard | ||||

| Cu | 80.0~88.0 | Fe | 2.5~5.0 | JIS | ASTM |

| Al | 8.0~10.5 | Zn | 0~0.5 | H5114 ALBC2 | B505 C95400 |

| Ni | 1.0~3.0 | Mn | 0.1~1.5 | CAC702 | |

| Tensile strength (N/mm²) | min.490 | ||||

| 0.2 Proof stress (N/mm²) | min.250 | ||||