C95500 Aluminum Bronze

C95500 Aluminum Bronze has an additional nickel content of up to 5.5%. This nickel component is the secret to helping this machine significantly enhance its mechanical durability, resistance to wear and corrosion. This is why C95500 Aluminum Bronze is the top choice for bushings, bearings, gears, and many other components that require high strength.

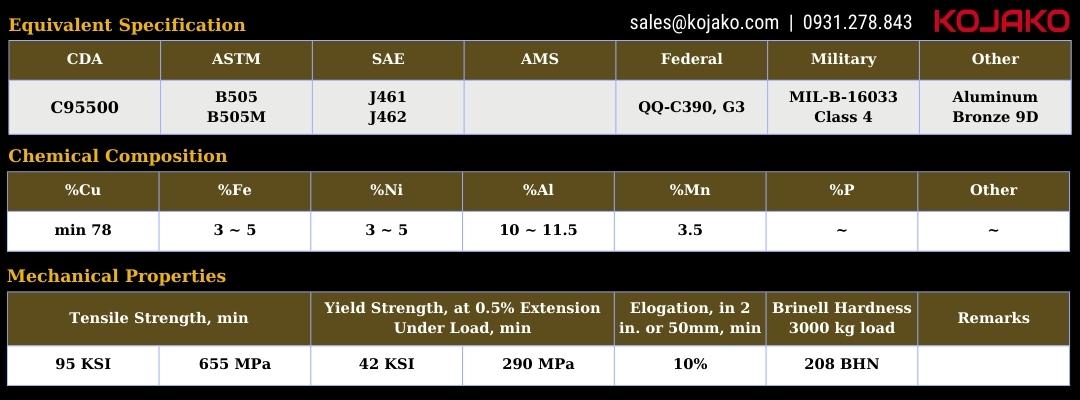

In particular, C95500 Aluminum Bronze easily demonstrates outstanding yield, compressive strength, hardness, impact resistance, and chemical resistance; At the same time, it can also be molded using many different methods. If you are looking for a quality, versatile, and reliable material, look to C95500 Aluminum Bronze. C95500 Aluminum Bronze not only that, C95500 is also strictly regulated according to ASTM, JIS, EN standards... giving you absolute confidence when using the product. Below are some outstanding features of C95500 Aluminum Bronze as follows:

1. Outstanding Strength and Hardness: With the addition of nickel up to 5.5%, alloy C95500 has very high mechanical strength and hardness, and has excellent resistance to force and abrasion. Furthermore, C95500 is pre-heat treated at the factory with the purpose of stabilizing the copper alloy after casting and at the same time increasing its hardness.

2. Good Stress Resistance: This alloy can withstand high pressure and mechanical stress, thus suitable for load-bearing applications in industry.

3. Abrasion and Corrosion Resistance: C95500 Nickel aluminum alloy is highly resistant to corrosion, especially in chemical environments and seawater.

4. Good Machinability: This alloy can be cast in many ways, creating strong and durable products.

5. Wide Application: With superior properties, C95500 Aluminum Bronze is widely used in many industries from marine, aviation, to military and machine manufacturing.

6. Tropical: The C95500 is resistant to high temperatures, making it suitable for applications that require rigorous work environments or temperature changes.

With all these properties, C95500 Aluminum Bronze is an excellent material for many industrial applications. Because of its good corrosion and abrasion resistance and wide range of industrial applications, C95500 Aluminum Bronze is a convenient and economical choice for those looking for a reliable material. C95500 Aluminum Bronze is famous in the industry for its excellent corrosion and abrasion resistance and high durability. Below are some typical applications:

1. Bushings and Bearings: Good wear resistance and high load-bearing capacity make C95500 Aluminum Bronze a top choice for processing applications as extremely good Bushings and Bushings.

2. Gears: Due to its good ability to withstand impact and abrasion due to friction, C95500 is often used in the production of gears, worms - worm gears, lead screws and nuts.

3. Marine and Aviation Equipment: C95500 Aluminum Bronze withstands the corrosive environment of seawater and chemicals well, so it is often used in the structure of ship propellers, pump shafts, aircraft parts and other components. Other military applications in detail covers for marine hardware, marine applications, marine hardware, ship building...

4. Machinery and Tools: Thanks to its high hardness and durability, C95500 Aluminum Bronze is often chosen as machine parts and machine tools serving the manufacturing and heavy industry, especially especially steel rolling.

5. Bearing Parts: The good bearing properties of C95500 Aluminum Bronze make it popular in applications located at high load points on aircraft lifting and landing equipment or load-bearing parts other.

6. Casting: C95500 Aluminum Bronze can be cast using many different methods, creating sturdy and durable products. But especially centrifugal casting, forging and continuous casting have very good properties and are often used as molds for plastic or glass casting.

7. Processing and manufacturing details and components of Pumps - Valves that work very well in seawater and chemical environments.

8. The detail parts for the heavy industrial systems as aircraft components, bearings, bushings, gears, glands, glass molds, handgun recoil mechanisms, hot mill guides, landing gear parts, machine parts, pickling equipment, piston guides, pump fluid ends, sewage treatment applications, valve bodies, valve components, valve guides, valve seats, wear plates, welding jaws, worms, worms wheels