C18150 Copper Chromium Zirconium

C18150 Copper Chromium Zirconium Are In Specialize For Resistance Spot & Seam Welding Electrodes. Good Hardness - High Heat & Corrosion Resistance.

C18150 Copper Alloy - Composition and Structure

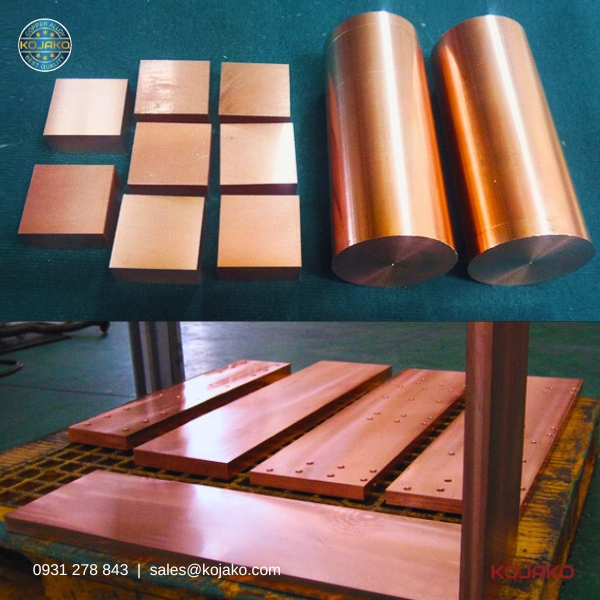

C18150 - Rod bars

C18150 Rod bars

C18150 Copper Alloy - Composition and Structure

Overview of C18150 Copper Alloy

C18150 copper alloy, also known as chromium zirconium copper alloy (or chromium copper alloy), is a copper alloy that is rich in chromium and zirconium. Its chemical composition consists of approximately 0.5-1% chromium and 0.03-0.1% zirconium.

C18150 copper alloy has excellent corrosion resistance, heat resistance, and high hardness. Due to these characteristics, it is often used as welding electrodes in applications that require high heat resistance and corrosion resistance.

The alloy's composition has been adjusted to create a material with excellent seawater resistance, making C18150 copper alloy widely used in the marine industry and applications related to seawater, such as shipbuilding, offshore drilling, and maintenance.

C18150 Chromium Copper Alloy

Composition - C18150 Copper Alloy

C18150 copper alloy is a high copper content alloy, with copper constituting over 97% of its composition. It has good thermal and electrical conductivity and is favored in the resistance welding industry.

C18150 is widely used in resistance welding processes, especially in the production of cap-type resistance welding electrodes. This alloy has high temperature resistance and high strength, ensuring high-quality welding results. Specifically, C18150 copper alloy is used in spot welding contact electrodes, seam welding discs/rolls, resistance welding, and electrode holders, among others.

In particular, the addition of zirconium to the chromium alloy improves its anti-sticking properties at high operating temperatures during spot welding of zinc-coated or plated materials. Additionally, the C18150 chromium copper alloy contains other elements such as zirconium (Zr) and aluminum (Al) as minor additives. These additives enhance its properties, including anti-sticking and corrosion resistance.

C18150 Chromium Zircomium Copper

Chemical Composition

- Tin (Sn): 0.5 - 1.5% (nominal: 1%)

- Zirconium (Zr): 0.05 - 0.25% (nominal: 0.1%)

- Copper (Cu): Balance (nominal: 98.9%)

Mechanical Properties:

- Tensile Strength: Maximum 70 MPa

- Conductivity: Maximum 85%

- Hardness: 70 - 85 HRB

Structure - C18150 Copper Alloy

C18150 copper alloy belongs to the face-centered cubic (FCC) crystal structure, which is known for its simple and rational crystal structure. This structure contributes to the alloy's flexibility and heat resistance. C18150 copper alloy also has physical properties such as a density of 8.89 grams per cubic centimeter. In summary, C18150 copper alloy is a widely used material in the resistance welding industry due to its excellent thermal and electrical conductivity, high strength, and high temperature corrosion resistance. Its composition and structure define its superior properties, including good thermal and electrical conductivity, anti-corrosion, and chemical resistance.

C18150 - Rod bars

C18150 copper alloy has various notable applications in different industries. Here are some typical applications of C18150 Copper Alloy:

1. Electronics Industry: C18150 is widely used in the electronics industry to produce critical components. Its high electrical and thermal conductivity, along with chemical resistance, make it an ideal material for manufacturing amplifiers, frequency adjusters, and other electronic devices.

2. Chemical Industry: C18150 copper alloy is used in the chemical industry, especially in the fabrication of chemical storage tanks and chemical processing equipment. With its good corrosion resistance and chemical resistance, this alloy ensures safety and durability for these applications.

3. Mechanical Engineering: With its high strength and hardness, C18150 copper alloy is used in mechanical applications such as hinges, machine parts, and construction materials. Its corrosion resistance and heat resistance also make it suitable for high-stress and harsh environments.

4. Other Applications: C18150 copper alloy can also be used in fields such as the production of heat-resistant electronic components, heat sinks, and medical applications like surgical tools and medical devices.

5. Resistance Spot Welding Industry: In the resistance spot welding industry, C18150 copper alloy has significant applications. With its excellent heat resistance, corrosion resistance, and chemical resistance, this alloy is suitable for resistance spot welding processes. It can withstand high temperatures and maintain stability during operation, ensuring high-quality and reliable resistance welding connections. C18150 copper alloy is also recognized for its good electrical and thermal conductivity, which improves heat transfer efficiency during welding. This minimizes heat and energy loss during the resistance spot welding process, while providing accurate and reliable connections for resistance welding applications.

C18150 Rod bars

However, the use of C18150 copper alloy in the resistance spot welding industry depends on the specific requirements and conditions of each application. To achieve the best results, it is important to adhere to the relevant regulations and technical guidelines regarding the use of this alloy in resistance spot welding processes.