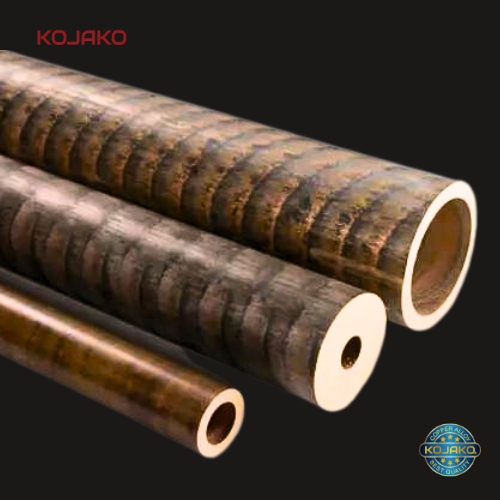

C83600 Leaded Gunmetal Bronze

C83600 Leaded Gunmetal Bronze

Copper Alloy C83600 contains up to 85% copper and 5% tin, the remainder is lead and zinc. With good anti-wear properties, it is widely used in detailed machining applications such as valves, pumps, bushings, gears, nuts... and other equipment in the chemical industry. matter.

Copper Alloy C83600 also has good oxidation resistance, helping parts work in harsh environments long-term and effectively. With its outstanding features, Copper Alloy C83600 is a great choice for machine parts that require high durability and long service life.

Because Copper Alloy C83600 contains main components including lead, zinc and tin, C83600 has excellent abrasion resistance, high durability and the ability to withstand great pressure. In addition, C83600 also has good corrosion resistance and is not affected by corrosive factors such as acids or alkalis. Therefore, this type of copper alloy is also used to produce chemical containers or equipment related to water treatment, especially machine parts or pumps, valves... working in seawater environments. Salty water.

Advantages of Copper Alloy C83600

1. Abrasion resistance: Copper alloy C83600 has high abrasion resistance, helping it maintain its original properties over a long period of time.

2. Good heat resistance: With high temperature resistance, C83600 is suitable for applications that require stability at high temperatures.

3. Easy to process: This type of copper is easily machined into products of complex shapes and sizes, making it an ideal choice for many technical applications.

4. Good electrical conductivity: This makes C83600 suitable for applications that require effective electrical conductivity such as in electronic devices.

Application of Copper Alloy C83600

1. Energy industry: C83600 is commonly used in the production and maintenance of high-temperature equipment, such as combustion chambers and high-temperature furnaces in thermoelectric furnaces.

2. Marine industry: This type of copper is popular in creating wear-resistant and high-temperature parts for ships and related equipment.

3. Automotive industry: Copper alloy C83600 is commonly used in applications where wear resistance and heat resistance are required, such as in cooling systems and engines.

4. Engineering Applications: In addition, it is also used in other applications such as valves and oil pipes, mechanical locks and parts, engines and water supply systems.

TYPICAL COMPOSITION C83600

|

CHEMICAL COMPOSITION |

MECHANICALPROPERTIES |

||||

|

Sn |

4.55% |

Al |

0.01% |

* Tensile Strength |

max. MPa 280 |

|

Zn |

5.85% |

P |

0.05% |

* 0.2% Proof Stress |

max. MPa 115 |

|

Pb |

5.7% |

Si |

0.02% |

* Elongation |

max. 30% |

|

Ni |

0.5% |

Cu |

Balance |

* Hardness |

70 BHN |