CAC403 Tin Bronze

CAC403 Tin Bronze is one of the high quality tin bronze alloys, with remarkable properties that bring a number of significant benefits to many mechanical applications in particular and modern industry. Generally speaking.

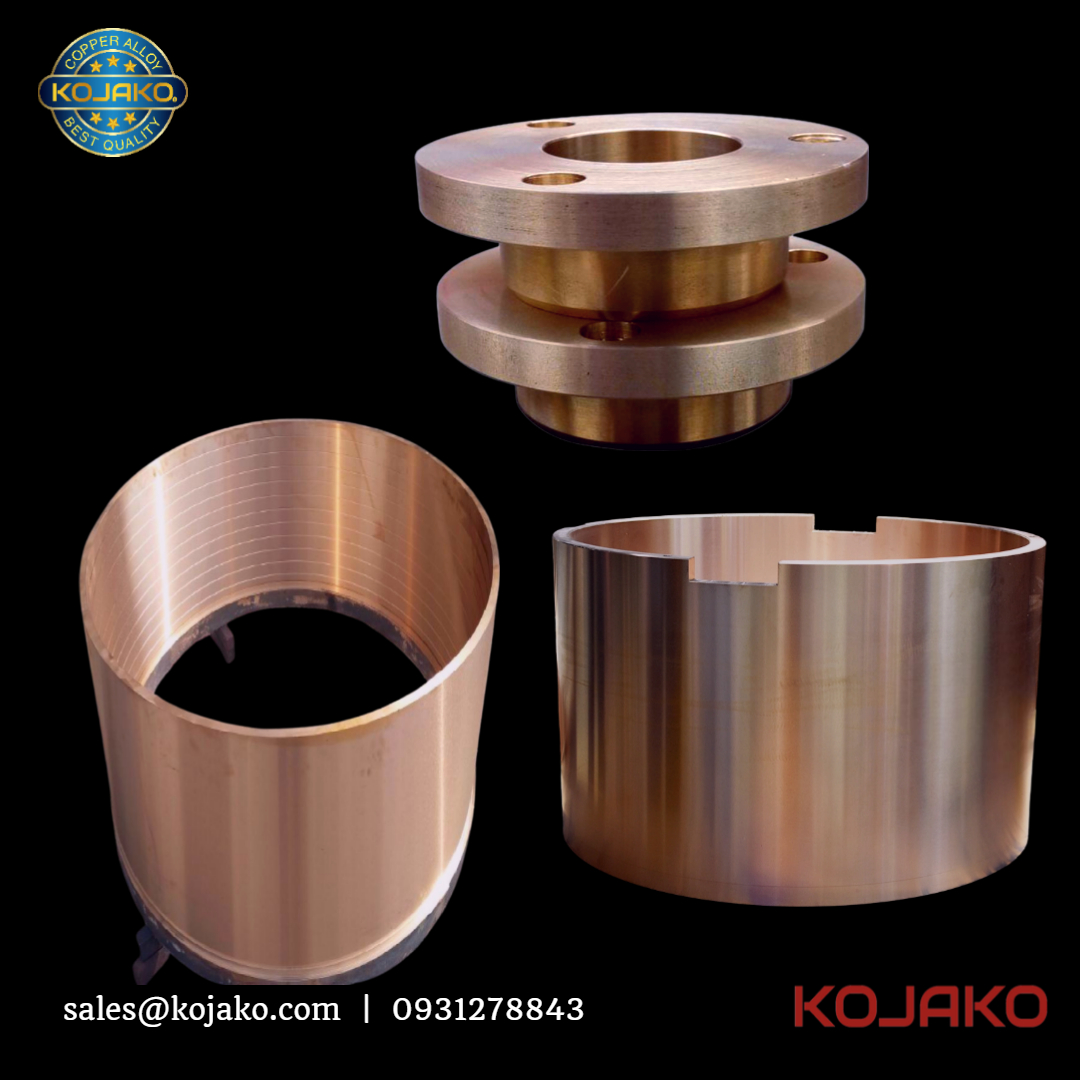

One of the main characteristics of CAC403 Tin Bronze is medium hardness but high ductility - tensile strength, helping to enhance abrasion resistance and impact resistance. This makes CAC403 material a popular and optimal choice for mechanical parts that require durability, such as bushings, bushings, racks and pinions, bearings and hydraulic pistons... At the same time, due to its high ductility, CAC403 Tin Bronze has good corrosion resistance, making it suitable for use in seawater environments or containing high salt concentrations. This makes CAC403 preferred in industries such as chemical, wastewater, marine - ship - valve pump equipment for drilling rigs and applications related to temperature control.

In addition, CAC403 Tin Bronze has the advantage of being easy to machine and shape, which allows the creation of complex and diverse products. This versatility makes it an ideal material for creating mechanical tools, molds and machine components. With the above properties, CAC403 Tin Bronze is an outstanding choice for mechanical applications requiring durability, average hardness and corrosion and abrasion resistance. Featuring easy machining, it offers flexibility in the design and production of high-quality mechanical products.

CAC403 Tin Bronze has many major applications in industries, below are some examples:

Machinery and mechanical industry: CAC403 Tin Bronze is used to process and produce mechanical machinery parts that require high strength and medium hardness, while CAC403 is used in the production of shafts. machines, gears, bearings, bushings, bushings, hydraulic pistons, washers - nuts and other load-bearing parts.

Chemical industry: With good corrosion resistance, CAC403 Tin Bronze is suitable for use in chemical environments. It is used in the production of pumps and valves, mechanical parts related to chemical processing and temperature control devices.

Irrigation and environmental industry: With high corrosion resistance and durability, CAC403 Tin Bronze is used in irrigation applications such as valves, water pumps, pipeline components and environmental treatment systems.

Marine industry: CAC403 Tin Bronze is used in the production of mechanical parts in the marine industry such as pipes, bushings, cooling systems and temperature-resistant parts. high pressure.

Energy industry: CAC403 Tin Bronze also has applications in the energy industry such as producing mechanical parts in electrical systems, thermal power systems and solar power systems.

These are just some specific examples of the main applications of CAC403 Tin Bronze and its use also depends on the specific requirements of each application and industry. To ensure the correct and effective choice, you should consult specific technical documents or consult with experts in the Copper Alloy industry - Kojako Vietnam Co., Ltd. Please contact our hotline or email us immediately.

|

CAC403 | BC3 JIS | C90500 ASTM - Mechanical Properties |

Standard | ||||

| %Cu | 86.5~89.5 | %Pb | max 1.0 | JIS | ASTM |

| %Sn | 9.0 ~ 11.0 | %Ni | max 1.0 | BC3 | C90500 |

| %Zn | 1.0 ~ 3.0 | %Fe | max 0.2 | CAC403 | |

| Tensile strength (N/mm²) | min.250 | ||||

| 0.5% Yeild strength (N/mm²) | - | ||||

| Elogation (%) | min.15 | ||||

| Hardness Brinell | min. 73 | ||||