CuSn12-C / EN 1982 CC483K

Tin bronze CuSn12-C (W-12) / EN 1982 CC483K

CuSn12-C / EN 1982 CC483K

Thành Phần Vật Liệu

| Tin bronze CuSn12-C (W-12) EN 1982 CC483K is suitable for Gears, worm wheels where shock resistance is required. Gears, Bearings for Heavy Loads and Relatively Low Speeds, Bearings, Gear Boxes, Speed Reducers, Valve Bodies, Worm Gears. | |

| Copper (Cu) | 85.0 ~ 88.5% |

| Tin (Sn) | 11.0 ~ 13.0% |

| Lead (Pb) | max. 0.70% |

| Zicum (Zn) | 3.0 ~ 5.0% |

| Furrum (Fe) | max. 0.20% |

| Nickel (Ni) | ma. 2.0% |

| Stibium (Sb) | max. 0.15% |

| Phosphor (P) | max. 0.60 |

| Sulfur (S) | max. 0.05% |

| Alluminium (Al) | max. 0.01% |

| Mn | max. 0.2% |

| Silic (Si) | max. 0.01% |

| Zn | max. 0.5% |

| Tensile Strength(Mpa, min.) | 300 |

| 0.5% Yield Strength(MPa, min.) | 150 |

| Elongation(min. %) | 5 |

| Harness (HB 10-1000) | 90 |

Product detail

Tin bronze CuSn12-C / Tin bronze CuSn12-C is formed and structured by the main material copper combined with tin alloy element to create the most special material composition in the field of copper alloy. The presence of tin provides high mechanical properties, in return the addition of tin will increase the cost of the metal but it brings high efficiency in the field of science, engineering and technology.

CuSn12-C tin alloy bronze is particularly suitable for certain applications in heavy industry. Depending on the application and technical requirements of load, speed and operating conditions of machinery and equipment systems, customers have the most appropriate choices. Because there are many types of Tin alloy Copper with a percentage of Tin, there are corresponding material codes such as CC480K-CuSn10-C, CC481K - CuSn11P-C, CC482K - CuSn11Pb2-C, CC483K - CuSn12- C, CC484K - CuSn12Ni2... (Material composition details will be introduced on each corresponding product code on the website). However, variations in chemistry, especially the addition of lead, are primarily designed to enhance machinability and pressure-tightness properties. Tin copper alloy CuSn12-C is quite typical and has stronger mechanical properties, the main application is used for processing Gears, bearings, bushings / Bushings, shaft bearings, pump bodies, guide shafts Engines and structural parts of load-bearing industrial machine systems, control valve stems...

CuSn12-C EN 1982 CC483K Tin Bronze is a copper alloy containing phosphorus and tin. It has an ideal combination of hardness, durability and abrasion resistance, making it a popular material in a variety of applications.

CuSn12-C EN 1982 CC483K Tin Bronze is widely used in the automotive industry, especially in the production of temperature gauges and oil nozzles. Its combination of hardness and durability helps it withstand high pressure and constant friction in harsh industrial environments.

One of the outstanding advantages of CuSn12-C EN 1982 CC483K Tin Bronze is its excellent wear resistance. This makes it the ideal material for use in parts subject to heavy friction. Besides, it also has good resistance to oxidation and corrosion, allowing it to maintain its performance and longevity in humid and acidic environments.

CuSn12-C EN 1982 CC483K Tin Bronze has good machinability and can be made into a variety of shapes and sizes. It has good weldability and can be machined using conventional precision machining methods, including turning, grinding and milling.

CuSn12-C EN 1982 CC483K Tin Bronze, has some outstanding features as follows:

1. High hardness: CuSn12-C EN 1982 CC483K This Tin Bronze has very good hardness, making it suitable for applications requiring resistance to pressure and abrasion.

2. Excellent durability: CuSn12-C EN 1982 CC483K Tin Bronze is able to withstand great pressure, creating an extremely durable and stable alloy.

3. Good abrasion resistance: CuSn12-C EN 1982 CC483K Tin Bronze does not wear easily when exposed to something, helping prolong life and performance in many applications.

4. Oxidation and corrosion resistance: CuSn12-C EN 1982 CC483K Tin Bronze shows resistance to oxidation and corrosion, helping it retain its performance and longevity in gloomy environments.

5. Good machinability: CuSn12-C can be made into many different shapes and sizes. At the same time, it can also be well welded and machined by conventional mechanical methods.

6. Versatile: With these properties, CuSn12-C EN 1982 CC483K Tin Bronze is well suited for a variety of industrial applications, especially in the automotive industry and the production of heavy friction parts.

Uses and Applications - CuSn12-C EN 1982 CC483K Tin Bronze:

1. Automobile industry: CuSn12-C EN 1982 CC483K This Tin Bronze is very popular in the auto industry. It is widely used in the production of parts such as temperature gauges and oil injectors.

2. Friction parts: Its excellent anti-wear properties make it the top choice for use in heavy friction parts.

3. Mechanical processing: CuSn12-C EN 1982 CC483K This Tin Bronze has good weldability and can be machined by conventional mechanical methods. Therefore, it can be made into many different shapes and sizes.

4. Corrosion resistance: CuSn12-C also has good resistance to oxidation and corrosion, which allows it to operate effectively in humid or acidic environments.

5. Manufacturing industry: This EN 1982 CC483K is also used in the manufacturing of machinery and equipment due to its high strength and hardness.

Due to this comprehensive characteristic, CuSn12-C EN 1982 CC483K Tin Bronze (EN 1982 CC483K) is truly an irreplaceable material in many industries and applications. Furthermore, CuSn12-C EN 1982 CC483K Tin Bronze (EN 1982 CC483K) is a multi-purpose material with high wear resistance, hardness and durability. This makes it an ideal choice for a variety of industrial applications, especially in the automotive industry and heavy friction parts manufacturing. So Copper CuSn12-C EN 1982 CC483K tin alloy is an optimal material for manufacturing mechanical parts and components that require high impact resistance with corrosion resistance, high durability and hardness, suitable for many industrial applications.

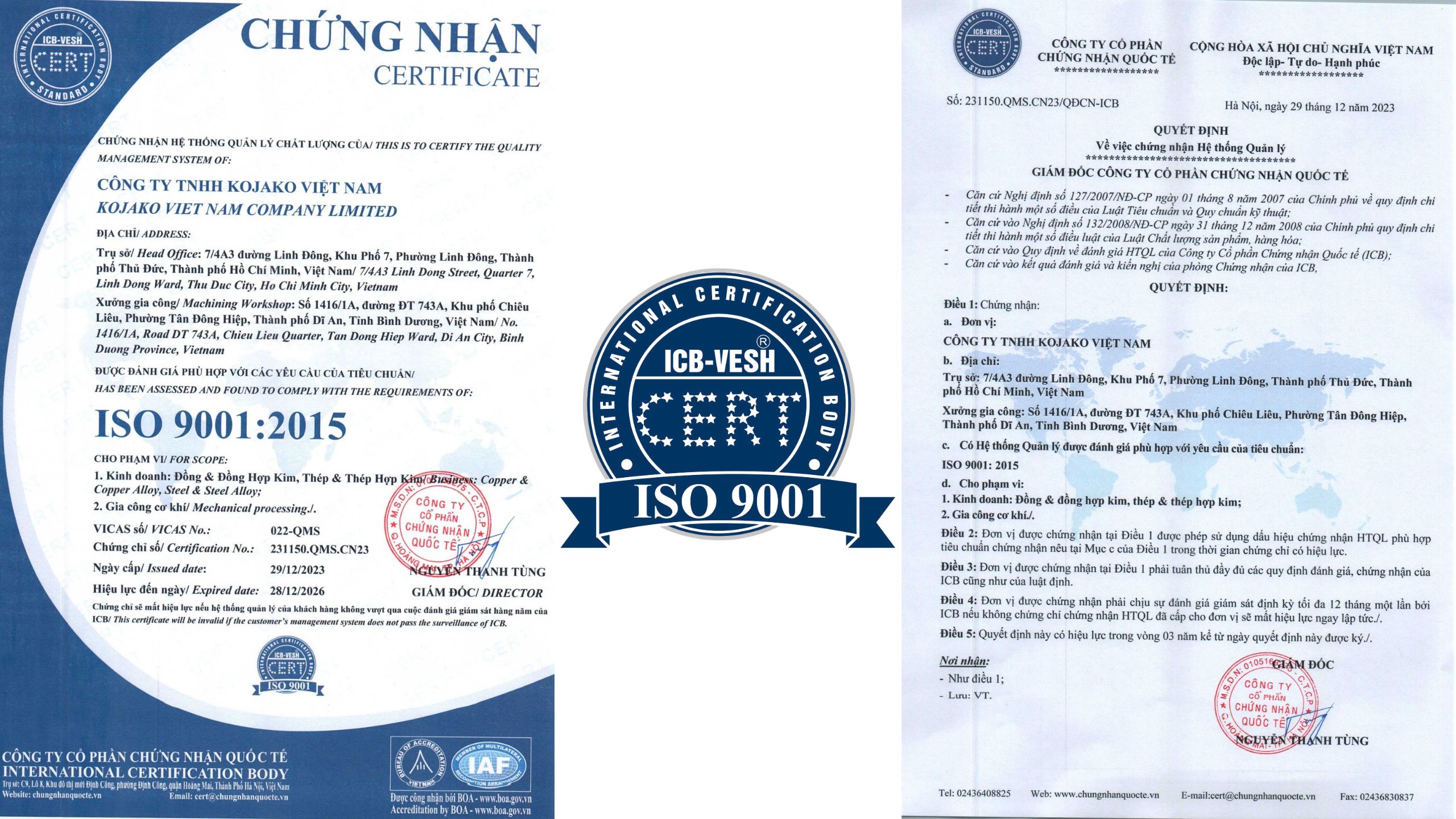

ISO 9001 : 2015 CERTIFICATE