C18150 - Class II

Chromium Copper Alloys

Thành Phần Vật Liệu

| Chromium Copper Alloys C18150 For Resistance Spot Welding & Seam Welding | |

| Copper (Cu) | 98.0 ~ 99.0% |

| Chromium (Cr) | 0.5 ~ 1.5% |

| Zirconium (Zr) | 0.05 ~ 0.25% |

| Electrical Conductivity (%IACS) | 80.0 ~ 85.0% |

| Tensile strength | 50 ~ 70 KSI |

| Hệ số giãn nở nhiệt ×106/K(20~300℃) | 16.45 |

| Tỉ trọng | 8.89 |

| Giới hạn nóng chảy | 1080 C |

| Giới hạn kết tinh | 1070 C |

| Modul đàn hỗi (kN/mm2) | 117000 |

| Độ dẫn nhiệt | 187.0 Btu |

| Độ cứng | 75 ~ 85 HRB |

Product detail

Chromium Copper Alloys C18150 RWMA Class II, One of the key advantages of chromium copper electrodes is their high thermal conductivity. This property allows the electrode to quickly and efficiently transfer heat to the workpiece, ensuring a strong weld. Chromium copper electrodes also have a high melting point, which makes them resistant to deformation and allows for extended use.

Another advantage of chromium copper electrodes is their durability. They are able to withstand the high pressures and stresses of resistance welding without degrading or deforming. This means that they can be used for a long time before needing to be replaced, which can help to reduce the overall cost of the welding process.

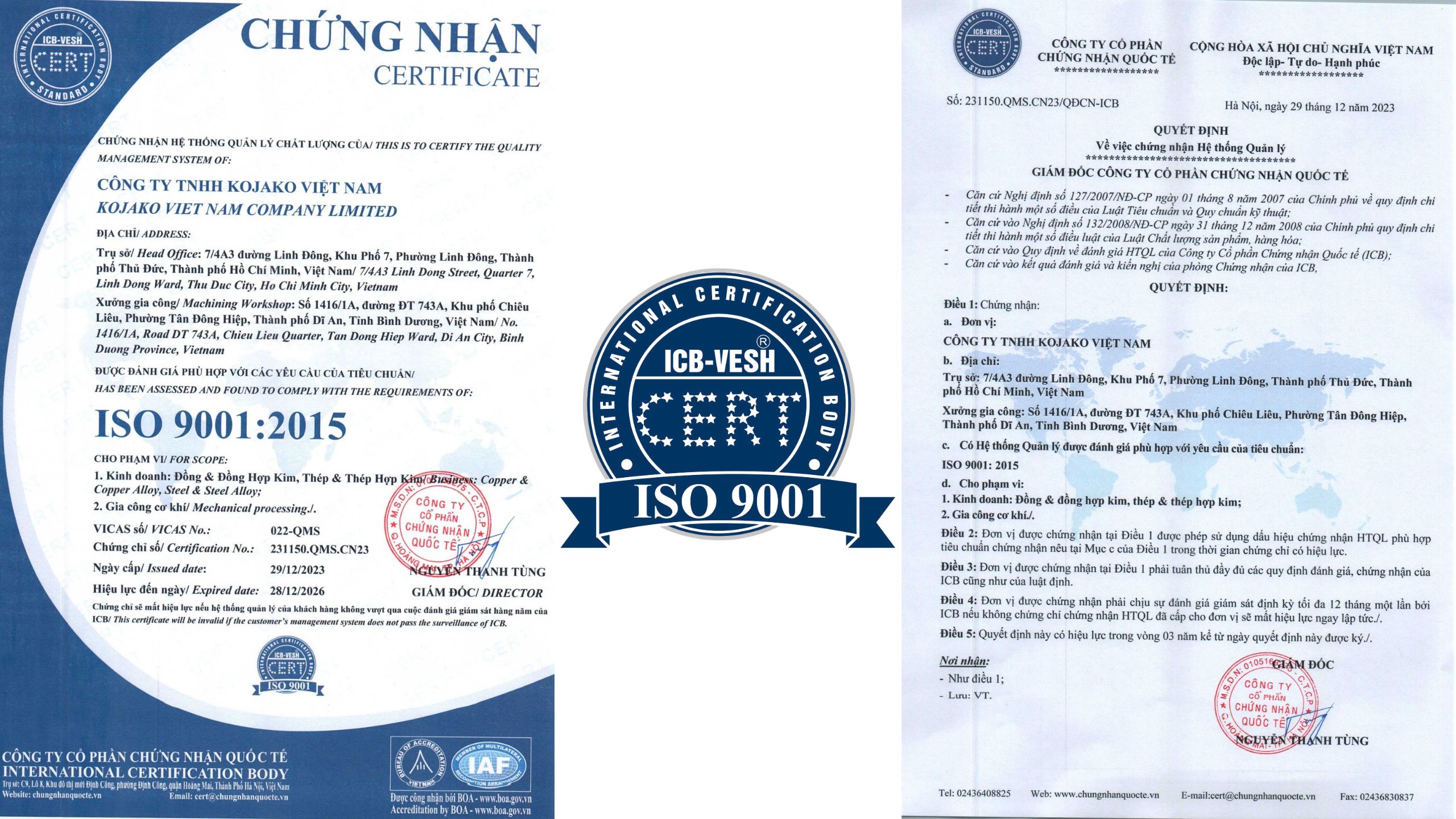

ISO 9001 : 2015 CERTIFICATE