C95800 (CAC703/ALBC3 JIS)

C95800 Aluminum Nickel Bronze

Thành Phần Vật Liệu

| Aluminum Nickel Bronze C95800 (CAC703/ALBC3 JIS) is good for bushings, gears, machinery, pickling equipment, propeller blades, propeller hub, shafts, valve bodies, wear plates, worm wheels, worms. In marine is to make covers for marine hardware, marine hardware, ship building, valves in contact with sea water. | |

| Copper (Cu) | 79% min |

| Lead (Pb) | max. 0.030% |

| Furrum (Fe) | 3.5 ~ 4.5% |

| Nickel (Ni) | 4.0 ~ 5.0% |

| Manganum (Mn) | 0.8 ~ 1.5% |

| Alluminium (Al) | 8.5 ~ 9.5% |

| Silic (Si) | max. 0.1% |

| 0.2% Proof Stress(N/㎟) | 240 min |

| Tensile Strength(Mpa, min.) | 585 min |

| Elongation(min. %) | 15 min |

| Hardness brinell | min. 150 HB |

Product detail

Aluminum Nickel Bronze C95800

Aluminum Nickel Bronze C95800 is produced as a standard copper alloy with the highest durability in the Aluminum Alloy Bronze group. Currently, Kojako Vietnam Co., Ltd. has many types of Aluminum Nickel Bronze such as C95400, C95500, AMS 4880-C95510 and C95900 as in-stock products, along with standard sizes such as round, tube and sheet shapes. rectangle. Aluminum alloy copper combined with iron and nickel acts as strengthening agent in these alloys including C958. All types of Aluminum Nickel Bronze can be heat treated, adding tensile strength to machined parts ensuring high load resistance. For this reason, Aluminum Nickel Bronze C95800 is always used to process gears, bushings, nuts, transmission shafts, racks, and valve pump parts working in high pressure environments.

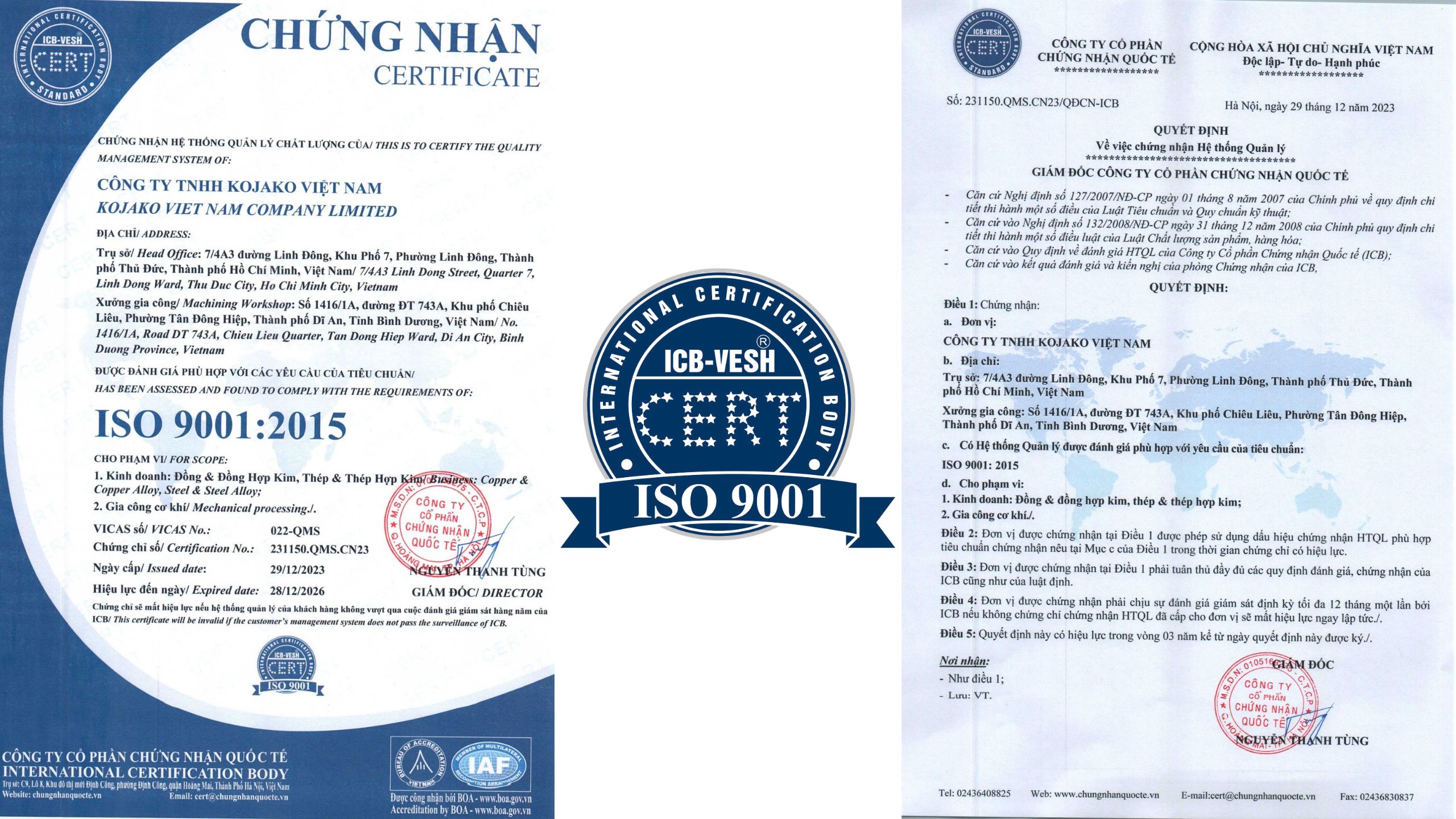

ISO 9001 : 2015 CERTIFICATE