C1020 Cu-OFC Copper

Pure Copper C10200 Cu-OFC

Thành Phần Vật Liệu

| Pure Copper C10200 / Cu-OFC is as Oxygen free copper is a 99.99% copper material and is the most special type in the industry, widely used in electronic, mechanical and construction applications. With its outstanding properties and high durability, Pure Copper C10200 / Cu-OFC has affirmed its position in replacing other materials. In this article, we will learn about the applications and characteristics of Pure Copper C10200 / Cu-OFC. |

Product detail

Đồng Nguyên Chất C1020

Pure Copper C10200 / Cu-OFC has been widely used for conductive parts due to its highest conductivity and thermal conductivity among industrial materials, and is also actively used in piping and water faucet parts with its excellent spreadability and corrosion resistance. When the copper is continuously used, the color gradually changes to a beautiful color called green patina. Of course, the patina is harmless to the human body.

Pure Copper C10200 Cu-OFC

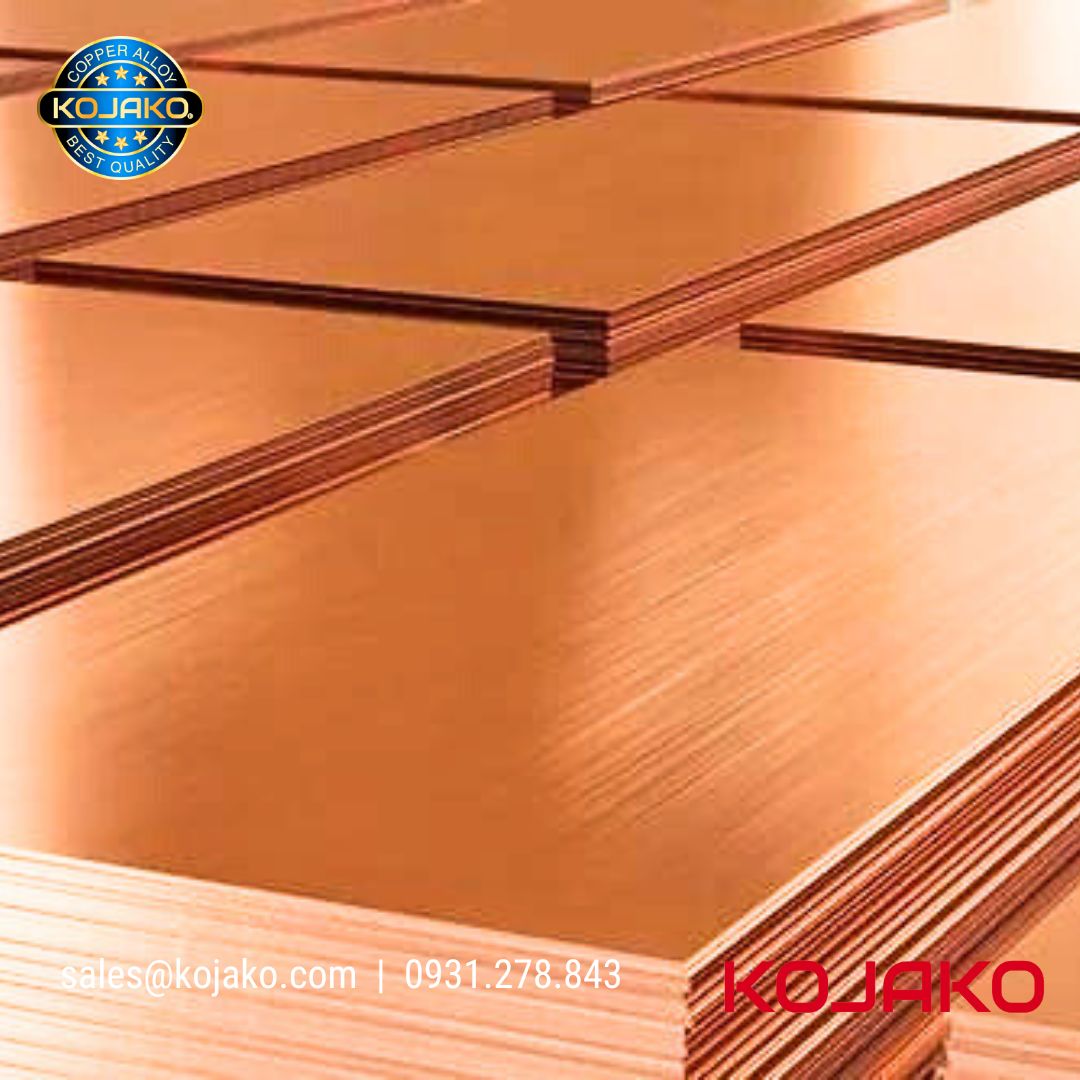

All Pure Copper C10200 / Cu-OFC is provided in the respective shapes such as a plate, a strip, and a bar by processing the high quality pure copper ingot supplied from one of the famous corporation in Japan.

Copper C1020 / Cu-OFC (Oxygen free copper) is a 99.99% copper material and is the most special type in the industry, widely used in electronic, mechanical and construction applications. With its outstanding properties and high durability, Pure Copper C10200 Cu-OFC has affirmed its position in replacing other materials. In this article, we will learn about the applications and characteristics of C1020 Oxygen free copper.

Đồng Đỏ Nguyên Chất C1020

Pure Copper C10200 / Cu-OFC is pure refined copper, with a pure copper (Cu) content of 99.99% or more. With such a high level of purity, C1020 Pure Copper ensures stable and reliable electrical, thermal and mechanical properties. The conductivity of C1020 Oxygen free copper reaches 101% IACS.

Pure Copper C10200 / Cu-OFC has many different applications in the fields of Electrical - Electronics industry, civil and construction fields. For example, it is used to produce electronic products such as cables, heat exchangers, printed circuits and broadcasting equipment, electrical wires, substation bus bars - electrical cabinets... In addition, Copper Pure C1020 is also used in the construction industry as plumbing systems, pipes and mechanical parts.

C1020 OFC Copper

Pure Copper C10200 / Cu-OFC has the following highlights:

- Thermoplastic properties: Pure Copper C10200 has good heat resistance, does not deform or lose important properties at high temperatures.

- Good electrical conductivity: With 101% IACS good electrical properties, C1020 Oxygen free copper is widely used in electronic applications, ensuring efficient and stable electrical conductivity.

- Acid and alkali resistance: C1020 Oxygen free copper is resistant to the effects of acids and alkalis, making it ideal for applications requiring the ability to withstand corrosive environments.

Oxygen-free-copper C1020 is not conductive and conducts heat well, spreads and drawings, has good welding properties, corrosion and weather resistance, and does not cause hydrogen deformation even when heated. High temperatures in a decreasing atmosphere. Oxygen free copper and tough pitch are used for:

Chemical & Physical Properties C1020 Cu-OFC.

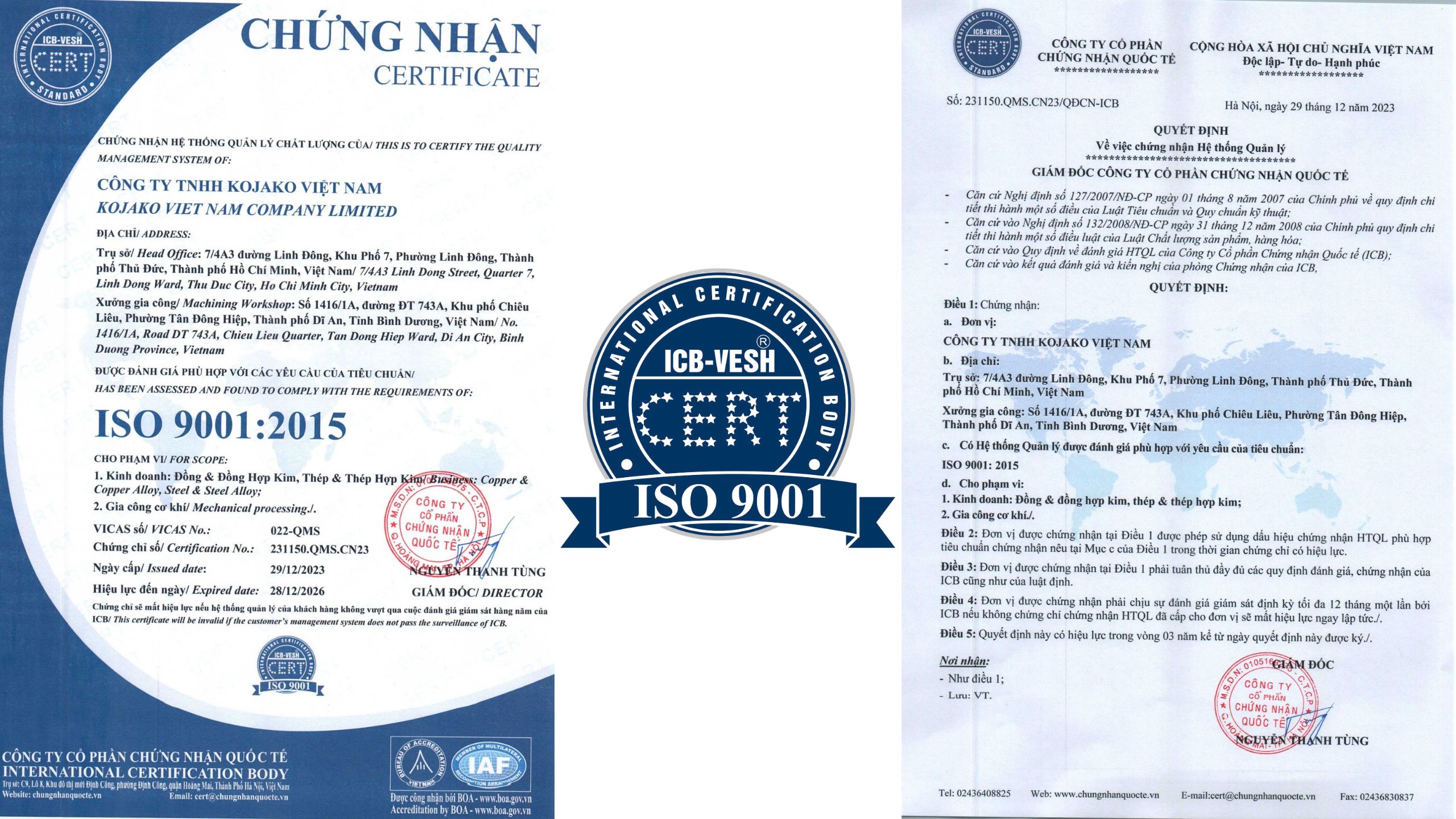

ISO 9001 : 2015 CERTIFICATE