C18150-Class II

Round Bar

C18150-Class II

Thành Phần Vật Liệu

| Đồng nguyên chất (Cu) | 98.0 ~ 99.0% |

| Chromium (Cr) | 0.5 ~ 1.5% |

| Ziconium (Zr) | 0.05 ~ 0.25% |

| Electrical Conductivity (%IACS) | 80.0 ~ 85.0% |

| Sức căng ( Tensile strength) | 50 ~ 70 KSI |

| Hệ số giãn nở nhiệt ×106/K(20~300℃) | 16.45 |

| Tỉ trọng | 8.89 |

| Giới hạn nóng chảy | 1080 C |

| Giới hạn kết tinh | 1070 C |

| Modul đàn hỗi (kN/mm2) | 117000 |

| Độ dẫn nhiệt | 187.0 Btu |

| Độ cứng | 75 ~ 85 HRB |

Product detail

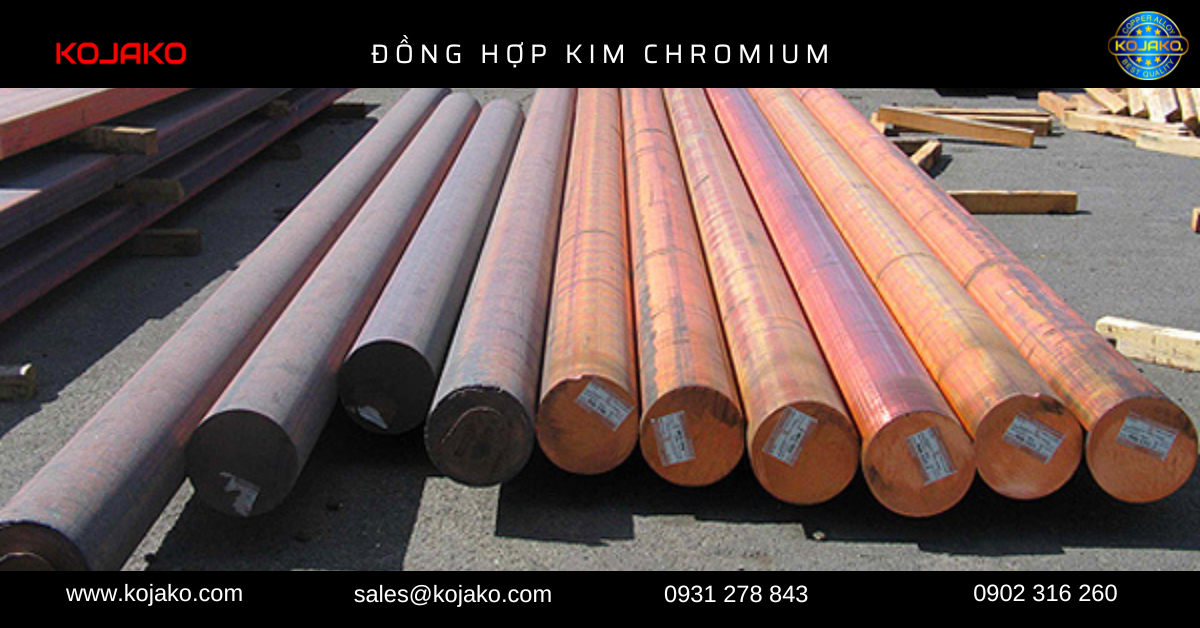

Chromium Copper Alloy for Resistance Welding Application

Resistance welding is a widely used technique in the manufacturing industry for joining two or more metal parts. It involves applying pressure and an electric current to the metal parts, which generates heat and fuses the parts together. The electrodes used in resistance welding are made of special alloys that can withstand the high temperatures and pressures involved in this process. One such alloy is chromium copper.

Chromium copper is a material that contains both chromium and copper. The addition of chromium to copper improves its strength, hardness, and resistance to wear and corrosion. These properties make it an excellent choice for use in resistance welding electrodes.

One of the key advantages of chromium copper electrodes is their high thermal conductivity. This property allows the electrode to quickly and efficiently transfer heat to the workpiece, ensuring a strong weld. Chromium copper electrodes also have a high melting point, which makes them resistant to deformation and allows for extended use.

Another advantage of chromium copper electrodes is their durability. They are able to withstand the high pressures and stresses of resistance welding without degrading or deforming. This means that they can be used for a long time before needing to be replaced, which can help to reduce the overall cost of the welding process.

In conclusion, chromium copper is an excellent material for use in resistance welding electrodes. Its high thermal conductivity, high melting point, and durability make it an ideal choice for this application. If you are in the manufacturing industry and are looking for a reliable and efficient material for your resistance welding electrodes, consider using chromium copper.

ISO 9001 : 2015 CERTIFICATE