C6191 Aluminum Bronze

C6191 Aluminum Bronze

C6191 Aluminum Bronze

Thành Phần Vật Liệu

| C6191 Aluminum Bronze has excellent wear resistance - corrosion resistance - fatigue resistance for good for Nut, Worm gears, Bush, Mold, Spiral gears. | |

| Copper (%Cu, min) | 81.0~88.0 |

| Alluminium (%Al) | 8.0~11.0 |

| Furrum (%Fe) | 3.0~5.0 |

| Nickel (%Ni) | 0.5 ~ 2.0 |

| Manganum (%Mn) | 0.5 ~ 2.0 |

| Tensile Strength (Mpa, min.) | 500 ~ 900 |

| Elongation(min. %) | 40 ~ 5 |

| Hardness (HBW, min) | 110 ~ 200 |

Product detail

C6191 Aluminum Bronze has high durability and good mechanical properties. Tensile strength is more than 685 MPa and C6191 Aluminum Alloy Copper has excellent wear resistance and corrosion resistance. This aluminum bronze is mainly used in industrial applications, especially in processing machine parts for transportation machinery, lifting and lowering cranes. More specifically, this aluminum alloy Copper is also optimally used to process Bearings, Rollers, Gears... in harsh working environments with abrasive heat and chemicals.

Because of this superior property, C6191 Aluminum Bronze is the top choice of manufacturers of machine parts and components in the high-tech industry. Through research and surveys, C6191 Aluminum Copper Alloy provided by Kojako Vietnam has a working time and lifespan many times longer than other domestic suppliers. Standard molding methods and material composition will bring great efficiency and performance. Therefore, this material is very popular for optimizing the processing of shaft bearings, ship gears, gear shafts, machine shafts.... for transportation vehicles, chemical industry, Oil and Gas Industry, Steel production industry, Corrugated iron manufacturer....

C6191 aluminum bronze is an alloyed metal with an aluminum content of less than 12% and an additional Manganese component, so it has excellent mechanical properties compared to other types of brass and copper alloys. Regarding physical and mechanical properties as follows:

- Mechanical properties: Good tensile strength. Good hardness and elongation, high impact and abrasion resistance. Very suitable in heavy industry

- Good abrasion resistance: Always chosen for processing machine parts that require high technical requirements by the manufacturer.

- Optimal resistance to chemicals and environments. Applied in the oil and gas industry and working in seawater environments.

For C6191 Aluminum Alloy Copper has optimal Abrasion - Corrosion - Anti-fatigue resistance, it is specialized in processing Nuts, Gears, Bushings, Molds, Bushings...

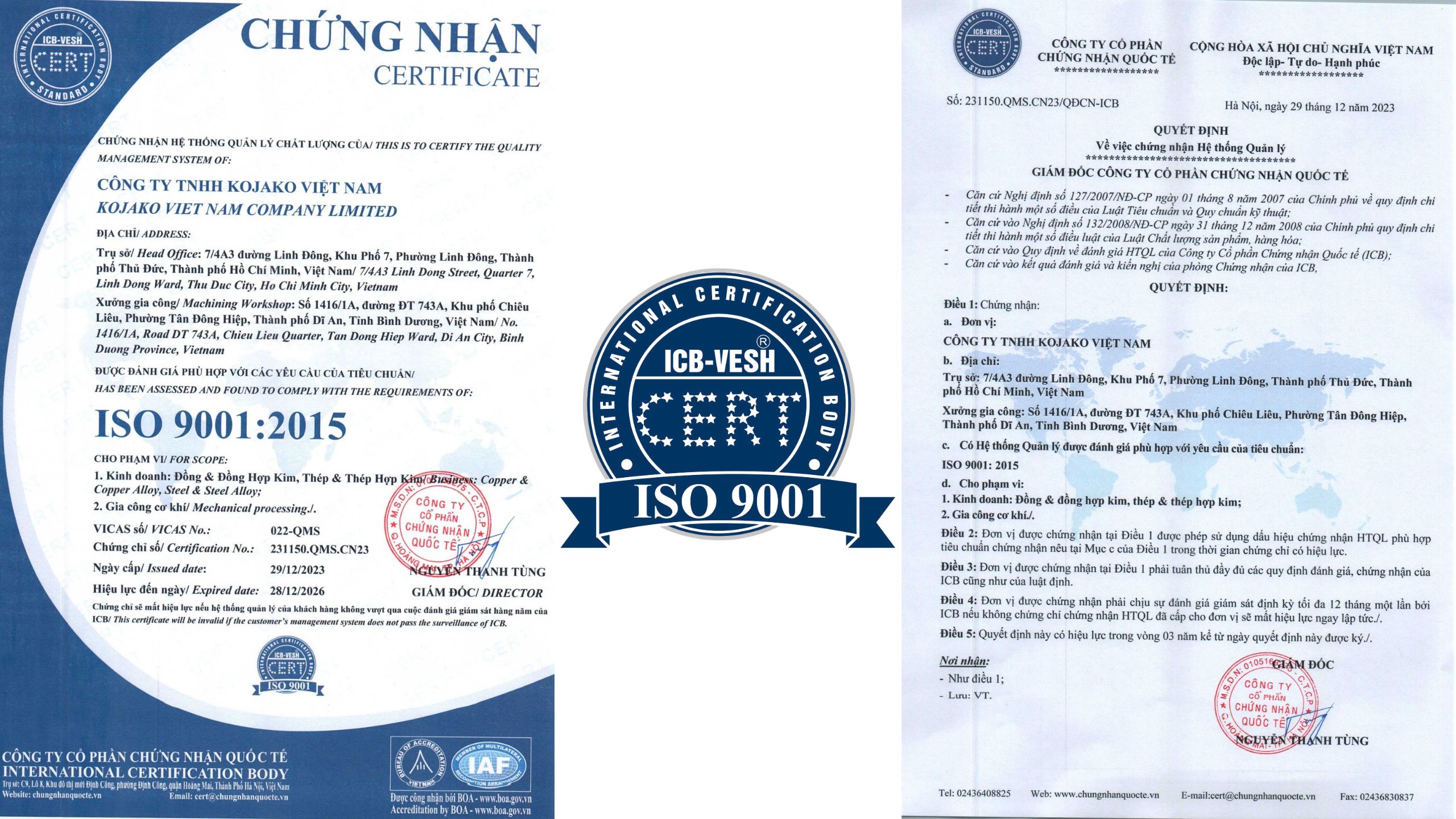

ISO 9001 : 2015 CERTIFICATE