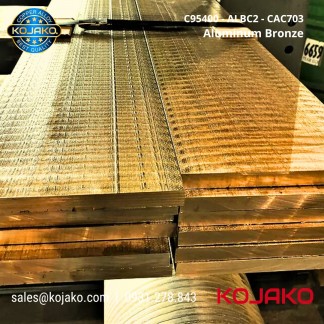

ASTM C95400 9C

C95400 Aluminum Bronze

Thành Phần Vật Liệu

| C95400 Aluminum Bronze “9C” provides high tensile, yield strength, good ductility, weldability and machinability, excellent resistance to wear, fatigue and deformation under shock, load. | |

| Copper (Cu) | 83% min |

| Aluminum (Al) | 10.5~11.5% |

| Ferrum (Fe) | 3.0~5.0% |

| Nickel (Ni) | 1.5% max (+Co) |

| Manganum (Mn) | 0.50% max |

| 0.2% Proof Stress(N/㎟) | 205 min |

| Tensile Strength(Mpa, min.) | 515 min |

| Elongation(min. %) | 13 min |

| Hardness | min. 140 HBW |

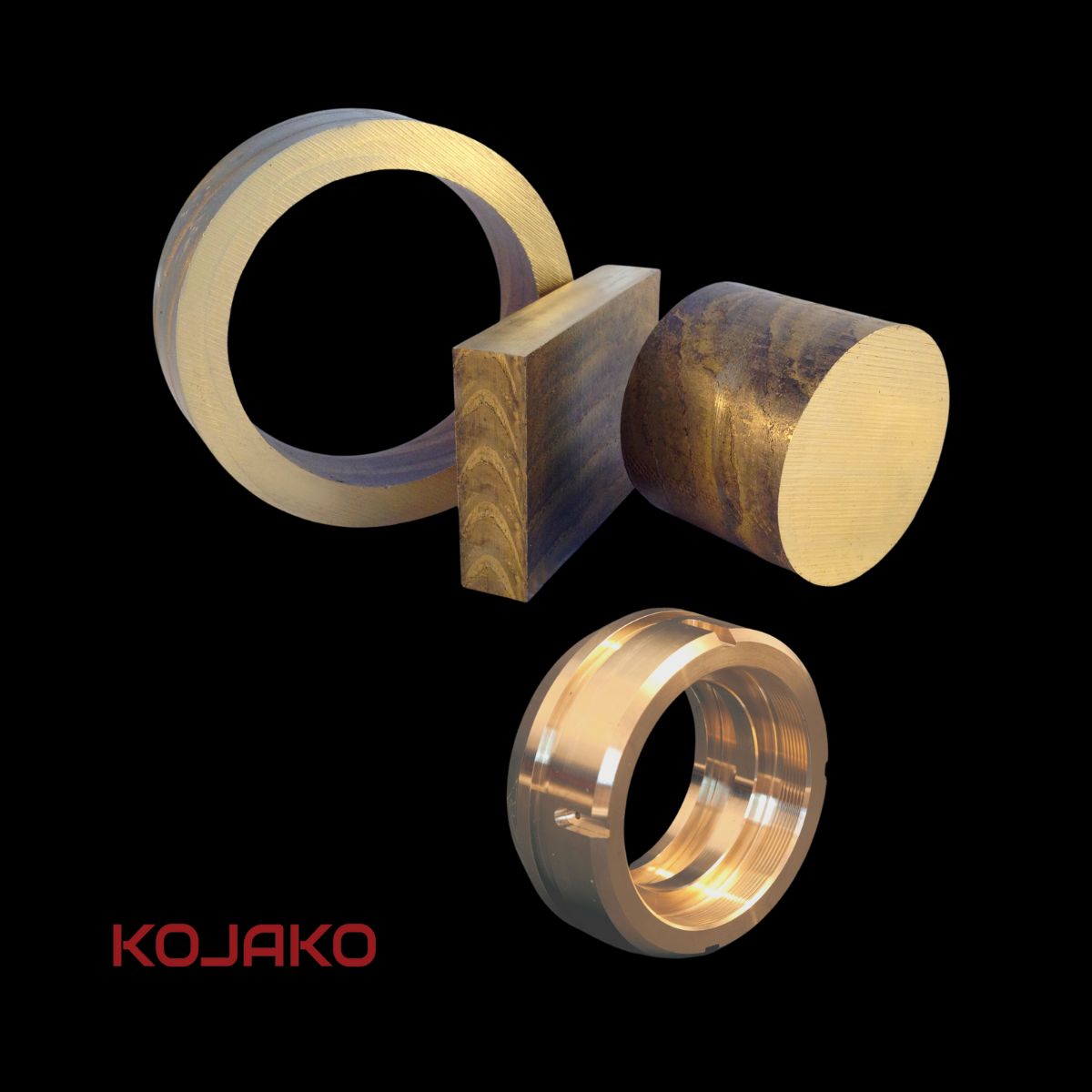

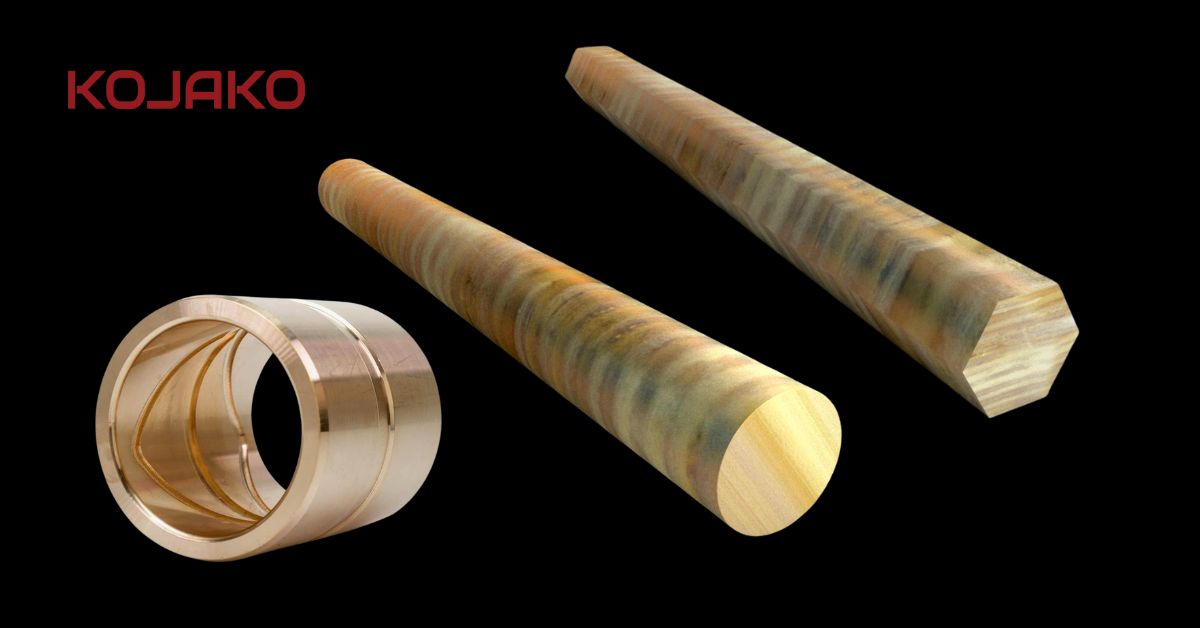

Product detail

Aluminum Bronze C95400 is well known for friction related applications while the Aluminum Copper or Nickel Aluminum Alloys group. They provide unique, impressive corrosion properties according to the requirements of pumps, propellers, valves and especially in seawater corrosion resistant applications. That characteristic makes C95400 Aluminum Alloy Copper the preferred solution for all marine related applications preferred by manufacturers.

Aluminum Bronze C95400 is an alloy of family consisting of copper, aluminum, nickel, iron and manganese. Each Odd individual software can be easily adjusted to improve the level, corrosion resistance and or machining capabilities. These combinations allow for a set of single owners in multiple application machines, ships, valves, sprockets ... Specifically:

Aluminum Bronze C95400 is an alloy of family consisting of copper, aluminum, nickel, iron and manganese. Each Odd individual software can be easily adjusted to improve the level, corrosion resistance and or machining capabilities. These combinations allow for a set of single owners in multiple application machines, ships, valves, sprockets ... Specifically:

Aluminium Bronze

ISO 9001 : 2015 CERTIFICATE